1. Introduction

The Mediterranean diet recommends the consumption of table olives on a daily basis due to its nutritional benefits associated with this fruit [1]. These advantages are linked in its composition rich in vitamins, minerals, fatty acids, mono unsaturated and phenolic compounds [2,3,4]. Table olives are one of the most popular fermented vegetables in the Western world, and particularly in the countries of southern Europe [5]. Olives may be consumed whole or in the form of a spread paste called "Tapenade".

In our previous work [6] we demonstrated how separating the pulp from the stone, before olive oil extraction, brings many benefits: On the one hand, the oil produced had a very low value of free acidity, a higher content of phenols and improved organoleptic characteristics, on the other, the obtainment of a pomace richer in natural antioxidants, pigments, phytosterols, vitamins and having a significant percentage of oil that can be a base of a spread pulp similar to "Tapenade". These olive pomaces could be eaten fresh, but, their very bitter taste prevent their immediate use. This bitterness is caused by the presence of oleuropein glycoside. Oleuropein is one of the major components in olives (Olea europea L.), present in high amount in unprocessed olive fruit [7]. Therefore, to make them more palatable and acceptable to consumers, they must be debittered. The Spanish method is the most used method today for debittering the olives and the process is more or less intense depending on the variety and maturation stage of the fruits [8].

The debittering process takes place with the use of sodium hydroxide (NaOH) solution which favors the elimination of the phenolic components contained in the fruits. The phenols, with oleuropein the main compound, are, in fact, responsible of the olive bitterness. Afterwards, the fruits are treated and washed with tap water before being placed in a brine where a spontaneous fermentation takes place [9]. NaOH treatments, however, cause complex physical and chemical changes in the fruits. The chemical treatment, in fact, leads to high losses in nutritional value and organoleptic characteristics of the processed olives [10]. Furthermore, the use of NaOH produces large volumes, between 3.9 and 7.5 m3/ton, of waste water highly contaminated. Considering the potential market of table olives as a "functional food", it is important to apply methods that do not require alkaline treatments. Also, preferences of current customers for natural and organic products [11], that receive no serious chemical treatments [12], are gaining more and more preference in the market. In addition, the use of NaOH is prohibited in many countries [13] so, the use of biological methods it is quite important. These latter methods imply the direct debittering of olives by means of acidified brines [14]. Very slowly, due to the spread of oleuropein from the pulp into the brine, olives will soften. However, this process takes a long time causing economic and technological problems for the industry [15].

Previous studies showed that foods produced by spontaneous fermentation are often characterized by marked sensory profiles [11,16,17,18]. However, the risk of bad smell and off-flavor production, due to the development of alteration microorganisms in uncontrolled biological processes, must be considered, as they may seriously affect the quality of the final products.

The purpose of this work was to develop mechanical strategies to improve olive paste sensory quality by modulating endogenous enzymes activity. The initial approach used in this study was similar to a normal debittering procedure of table olives applied directly to the olive pomace straight after olive oil extraction [19]. Experimental parameters, afterwards, have been optimized in order to determine the best treatment conditions so that the natural fermentation process could be controlled and oriented for reducing the debittering phase time, the unwanted microorganism growth and the water consumption.

2. Materials and method

2.1. Plant material: Olive samples

This survey was conducted on olives from Chemlali variety, whose trees are cultivated in the centre and south Tunisia, which occupies 60% of the olive cultivation area. Chemlali variety olive tree is vigorous and characterized by its richness in pollen. The average yield of oil is 20% and contributes for more than 30% to national production. Olives were harvested with a maturity index of 4.74, corresponding to a purple/black skin color and a half purple flesh.

2.2. Olive pomaces

Olive pomaces were obtained by mean of the experimental device optimized in our previous work with the aim of developing a more ecological and economical sustainable system for olive oil extraction [6]. This new facility is composed of a destoner and a two-phase extraction system producing three final products: A pulp olive oil rich in natural antioxidants, a stone olive oil for cosmetic application, and an olive pomace for food consumption [6]. The peculiarity of this system is that the olives are treated before they are put into the new oil mill. To facilitate the separation of the olive pulps from the stones, and to decrease the time for the lactic fermentation of the pulps, fresh olives (100 kg) are carefully placed in an oven for 20 min at 35 ℃. The de-stoned olive paste is then mixed at 30 ℃ for 35 min and centrifuged to obtain a pure olive pulp oil and a pomace. No water addition is needed.

2.3. Fermentation processes

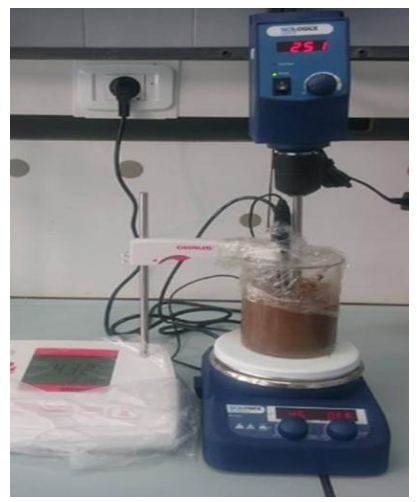

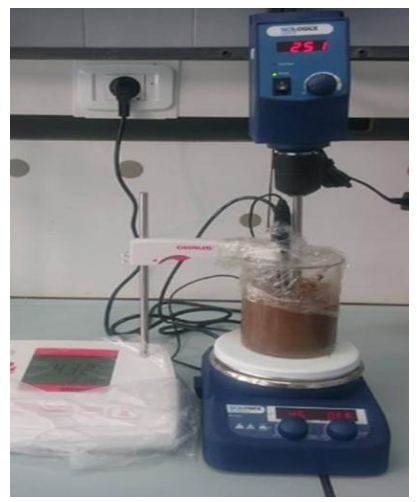

The olive pomaces, obtained as described in Section 2.2, have been subjected to different fermentation processes in order to establish the best debittering conditions. Many studies have investigated how to achieve a proper fermentation of whole olives, but, to our knowledge, the lack of data on the direct debittering of olive pomaces obtained directly after oil extraction, made it necessary to evaluate and estimate parameters such as temperature, pH and saline concentration of the brines. At the beginning, in fact, the natural fermentation of the pomaces by means of brines containing 6% and 8% of sodium chloride (NaCl) at 20 ℃ and 40 ℃, respectively, was accompanied by bad smell and off-flavor due to microorganism's development during uncontrolled biological processes. So, it was considered to improve the brines by adding additives such as glucose, yeast extract and lactic acid. At the end, before undergoing to fermentation processes, olive pomaces were heated with water vapor through a double wall membrane until reaching a temperature between 35 and 40 ℃ (optimal temperature to activate oleuropein's hydrolysis enzymes) and, for optimizing the contact between substrates and enzymes and avoiding undesirable surface layers, an agitator was used for a better diffusion of the substances in the brines which were acidified by adding a powder prepared from older brines (Figure 1). The experimental study was, therefore, performed on the following preparations:

– Olive pomace in a brine of 6% NaCl (B);

– Olive pomace in a brine of 6% NaCl synthetically modified by adding glucose (0.5%), yeast (0.01%) and lactic acid extract (0.5%) (BSM);

– Olive pomace in a brine of 6% NaCl naturally modified by adding an old brine powder (10%) (BNM);

– Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl (BH);

– Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl synthetically modified by adding glucose (0.5%), yeast (0.01%) and lactic acid extract (0.5%) (BHSM);

– Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl naturally modified by adding an old brine powder (10%) (BHNM).

All the fermentations were monitored weekly for a month by performing physico-chemical assessments. For quality control purpose, fermentation of whole olives was also considered.

2.4. Physico-chemical analysis

2.4.1. Total phenols determination

Total phenols content was determined using Folin-Ciocalteu reagent [20] as follows: 10 g of homogenized olive pomace were put in a screw cap test tube with 20 mL of methanol/water solution (80/20; v/v). After 30 min of stirring, the solution was centrifuged at 4000 rpm for 10 min. The methanol-water phase (phenolic extract) was collected and diluted (1/2; v/v). The extracts (100 μL) and gallic acid standard solutions were left to react with 500 μL of Folin-Ciocolteu reagent for 5 min at room temperature; afterward, 3 mL of 20% Na2CO3 solution and ultra-pure water were added to make up the final volume of 10 mL. The reaction mixtures were left in the dark at room temperature for 80 min before spectrophotometric analyses by means of a Varian Cary 50 UV-VIS spectrophotometer. For quantification, a calibration curve was obtained using gallic acid as external standard (200–2000 mg/kg) and the results (Table 1) were expressed as mg/kg of gallic acid [21].

Table 1. Olives and pomaces physico-chemical and sensory analysis results obtained at different times of collection (2, 3 and 4 weeks), at a concentration of 6 and 8% of NaCl (and at a temperature between 20 and 40 ℃). Tasters assessed the overall acceptability of each sample taking into account all non-flavor and undesirable taste using a numerical scale from 1 to 9 (1 for not acceptable and 9 for very good). Bitterness was evaluated by a numerical scale from 1 to 9 (1 for no bitterness and 9 for extremely bitter). In the end, an overall preference was expressed. Total phenols in brine were expressed in mg/kg. Different letters (a–c), within values, indicate the significant difference (p < 0.05) between the samples in relation to the different variables.

|

Material |

Time (Weeks) |

Temperature (℃) |

NaCl (%) |

Acidity (%) |

pH |

Phenols (mg/kg) |

Smell |

Bitterness |

Salinity |

Abnormal Fermentation |

Global Acceptability |

| 1 |

olives |

2 |

20 |

6 |

0.21a |

4.00a |

2930c |

4.56a |

6.98c |

5.87a |

2.96b |

4.34a |

| 2 |

pomace |

2 |

20 |

6 |

0.24a |

4.80c |

2790c |

4.89a |

5.76b |

5.44a |

2.09b |

4.98a |

| 3 |

olives |

3 |

20 |

6 |

0.25a |

4.60c |

2694c |

5.32b |

6.54c |

5.32a |

2.54b |

4.44a |

| 4 |

pomace |

3 |

20 |

6 |

0.28b |

4.52c |

2483c |

5.52b |

5.97b |

5.72a |

2.34b |

5.16b |

| 5 |

olives |

4 |

20 |

6 |

0.29b |

4.20b |

2418c |

6.09c |

6.73c |

5.98a |

2.98b |

5.12b |

| 6 |

pomace |

4 |

20 |

6 |

0.31b |

4.42b |

2258b |

6.07c |

5.54b |

5.65a |

2.76b |

5.67b |

| 7 |

olives |

2 |

40 |

6 |

0.37b |

4.23b |

2314b |

5.98b |

5.34b |

5.34a |

1.02a |

7.32c |

| 8 |

pomace |

2 |

40 |

6 |

0.42c |

4.26b |

2240b |

5.54b |

4.67ab |

5.49a |

1.08a |

7.41c |

| 9 |

olives |

3 |

40 |

6 |

0.39c |

4.20b |

2385b |

5.72b |

4.78ab |

5.65a |

1.43a |

7.11c |

| 10 |

pomace |

3 |

40 |

6 |

0.44c |

4.10a |

2112b |

5.90b |

3.65a |

5.88a |

1.56a |

7.15c |

| 11 |

olives |

4 |

40 |

6 |

0.38c |

4.00a |

2300b |

6.04c |

4.98b |

5.74a |

3.67c |

4.65a |

| 12 |

pomace |

4 |

40 |

6 |

0.43c |

4.00a |

1970a |

6.13c |

3.45a |

5.51a |

3.98c |

4.69a |

| 13 |

olives |

2 |

20 |

8 |

0.20a |

4.12b |

2187b |

4.64a |

6.86c |

7.16b |

2.95b |

4.12a |

| 14 |

pomace |

2 |

20 |

8 |

0.21a |

4.76c |

2000a |

4.34a |

5.79b |

7.09b |

2.76b |

3.90a |

| 15 |

olives |

3 |

20 |

8 |

0.22a |

3.80a |

2210b |

5.98b |

6.65c |

7.95b |

2.32b |

4.56a |

| 16 |

pomace |

3 |

20 |

8 |

0.23a |

4.50c |

1934a |

5.32b |

5.34b |

7.65b |

2.87b |

4.11a |

| 17 |

olives |

4 |

20 |

8 |

0.23a |

4.40b |

2019a |

5.85b |

5.43b |

7.34b |

2.21b |

4.32a |

| 18 |

pomace |

4 |

20 |

8 |

0.24a |

4.20b |

1954a |

6.02c |

4.12a |

7.23b |

2.43b |

4.38a |

| 19 |

olives |

2 |

40 |

8 |

0.32b |

4.32b |

2348b |

6.67c |

5.76b |

7.54b |

4.98c |

5.32b |

| 20 |

pomace |

2 |

40 |

8 |

0.38c |

4.24b |

2100b |

6.43c |

4.98b |

7.93b |

5.03c |

5.12b |

| 21 |

olives |

3 |

40 |

8 |

0.35b |

4.20b |

1976a |

7.01c |

5.08b |

7.07b |

5.56c |

5.30b |

| 22 |

pomace |

3 |

40 |

8 |

0.39c |

4.23b |

1786a |

7.03c |

4.32a |

7.16b |

5.64c |

4.90a |

| 23 |

olives |

4 |

40 |

8 |

0.34b |

4.00a |

2011a |

7.67c |

3.98a |

7.65b |

5.76c |

4.87a |

| 24 |

pomace |

4 |

40 |

8 |

0.39c |

4.00a |

1825a |

7.14c |

4.04a |

7.32b |

5.89c |

4.67a |

2.4.2. Sensory analysis

The resulting olives and olive pomaces soaked in brine were placed in plastic dishes for evaluation of their sensory properties, using the method described by Lalas and co-workers [22]. Briefly, twelve panelists were selected among students and laboratory personnel and the sensory evaluations were carried out at Sensory Evaluation Laboratory of the Public Research Institute of Tree located in Sfax, Tunisia. The Institute, supervised by the Ministry of Agriculture, is specialized in olive growing and has the task of undertaking all the research, study and experimentation activities that can develop and promote the olive sector in semi-arid zones at agronomic, technological and economic levels. Each sample was labeled with a three-digit code. Each panelist has conducted, individually, the tastings in a cabin provided with tap water to rinse the oral cavity between a taste and another. Before tasting, to align all the panel jury, tests for the salinity, bitterness and acidity were performed using sodium chloride, quinine and lactic acid as reference standards, respectively. Moreover, to set a scale of intensity for the "bitterness", commercial olives and olive pomaces were used. Samples were prepared and served following the instructions regulated by the International Olive Council for the sensory analysis of table olives (COI, 2011). The sensory data elaborations were conducted as recommended in Annex 1 of the Regulation (COI/OT/MO/n_1/Rev.2 Annex 1 Method for calculating the median and the confidence intervals) (COI, 2011). Samples were considered as debittered when no significant differences were found between experimental samples and commercial reference. Tasters assessed the overall acceptability of each sample taking into account all non-flavor and undesirable taste using a numerical scale from 1 to 9 (1 for not acceptable and 9 for very good). Bitterness was evaluated by a numerical scale from 1 to 9 (1 for no bitterness and 9 for extremely bitter). Moreover, an overall preference was expressed [22] (Table 1).

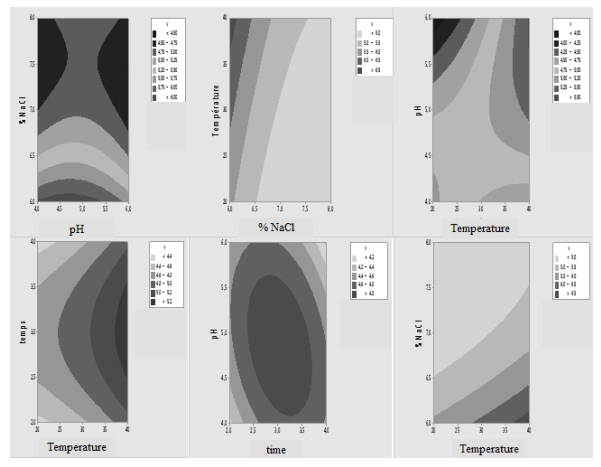

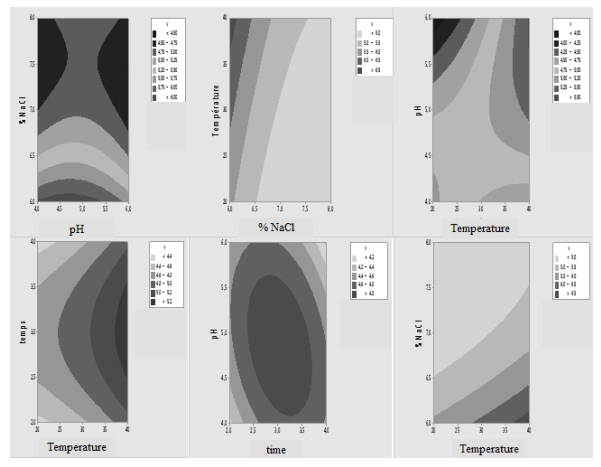

2.5. Statistical analyses: Plan Box-Behnken

In order to obtain a final product accepted by consumers, the best treatment conditions to perform on olive pomaces were evaluated. By means of Box-Behnken analysis, a plan has been created in order to optimize the acceptability of the panel jury. In this plan, three levels have been attributed to four selected factors (X1: Fermentation time of 2, 3 and 4 weeks; X2: Temperature at 20, 30 and 40 ℃; X3: Brine at pH of 4, 5 and 6 and X4: NaCl concentration of 6, 7 and 8%). Twenty four experiments were carried out to estimate the coefficients of the model. The relation between the acceptability for consumers and the four selected quantitative variables was represented by the following second order polynomial equation:

|

Y=31.0+2.94X1−0.103X3−8.36X4−0.280X2∗X2+0.559X4∗X4+0.052X1∗X4+0.0555X2∗X3+0.115X2∗X4−0.0268X3∗X4.

|

3. Results and discussion

3.1. Influence of the treatment conditions

The olive pomace that remains after the extraction of the oil by means of the experimental device described in Section 2.2 is a complete product with important nutritional properties [23]. The restriction that prevents the use of this fresh by-product is its very bitter taste, so, a pretreatment stage is required to eliminate it. From the experimental trial, the elimination of phenols from olive pomaces requires a period of three weeks in a brine with a low concentration of NaCl (6%) (Table 1). A very important factor to consider when olive pomaces are used instead of whole olives is its exchange surface. In the production of table olives, the debittering process could take months depending on the salt concentration of the brine [7,24,25]; in fact, the olive skin, acting as a barrier, protects the fruit. Using olive pomaces, instead, the loss of oleuropein was registered after three weeks of maceration at 40 ℃ confirming that the hydrolysis of this compound is carried out more easily at higher temperatures (30–40 ℃) [26]. Several studies have reported that β-glucosidase activity, in fresh fruit, is strongly dependent on the temperature; in particular, at a temperature of 30 ℃, the β-glucosidase activates to be eliminated at 90 ℃ [7]. Other studies indicate that the acidic conditions of the brine can also favor the chemical hydrolysis of oleuropein [27,28,29]. Knowing that the chemical hydrolysis of oleuropein occurs slowly between a pH of 3.8 and 4.2, modulating this enzymatic reaction, it is possible to optimize the natural debittering process of table olives. The panel jury found no differences between debittered olive pomaces and traditionally debittered table olives. The resulting olive paomaces were, in fact, characterized by a fruity aroma and a slightly bitter taste well accepted by the testers.

3.2. Optimization of the panel's acceptability to the tested products using experimental plans methodology—Plan Box-Behnken

ANOVA analysis was applied to a set of parameters that intervene in the debittering process of whole olives and olive pomaces to assess the influence of significant factors over residual error. Box-Behnken plan has been used for determining the optimal levels for the four selected variables (X1: Fermentation time of 2, 3 and 4 weeks; X2: Temperature at 20, 30 and 40 ℃; X3: Brine at pH of 4, 5 and 6 and X4: NaCl concentration of 6, 7 and 8%). The sensory analysis results were supplemented by R and Minitab software in order to estimate the importance of each parameter. The first result was a coefficients table for determining the parameters that significantly influence the sensory profile. From the ANOVA response, fermentation time is a significant factor at 10%. In fact, by increasing the contact between substrate (olive pomaces) and endogenous enzymes, secreted by lactic bacteria, the hydrolysis and the transfer phenomena improve. Temperature and NaCl concentration were, instead, considered significant at 1%. The interaction between fermentation time and salt concentration, as well as the interaction between fermentation time and processing temperature, changes significantly the natural course of the debittering process. Also, it was interesting to understand more about the interaction between NaCl concentration and the temperature of the brines and their effects on the transfer of phenols in the natural fermentation processes. The interaction between the four parameters showed significant effects. There were, in fact, effects on the time, temperature and NaCl concentration since critical variability was less than 5% (Table 2). An experiment conducted on natural green olives from Manzanilla cultivar demonstrated the influence of the temperature on the reaction of oleuropein hydrolysis. In particular, oleuropein hydrolysis rate resulted temperature dependent with statically significant differences [30].

Table 2. Model validation table built in order to test the independence of residues for ANOVA model tested with R software. X1: pH; X2: Fermentation time (week); X3: Brine temperature (℃); X4: % NaCl; Y: Global acceptability of the panelists; Sum Sq: Sum of squares of deviations from the average; df: Degrees of freedom; Mean Sq: Mean square. Probabilities are indicated by: * p < 0.05,

** p < 0.01 and ***p < 0.001.

|

df |

Sum Sq |

Mean Sq |

F value |

Pr (>F) |

Signif |

| Time |

1 |

1.07 |

1.07 |

4.68 |

0.006 |

** |

| pH |

1 |

0.01 |

0.01 |

0.08 |

0.78 |

|

| Temperature |

1 |

7.49 |

7.49 |

32.75 |

0.00 |

*** |

| % NaCl |

1 |

6.47 |

6.47 |

28.31 |

0.00 |

*** |

| Time*Time |

1 |

0.95 |

0.95 |

2.30 |

0.15 |

|

| pH*pH |

1 |

0.51 |

0.50 |

1.23 |

0.28 |

|

| Temperature*Temperature |

1 |

0.02 |

0.02 |

0.06 |

0.80 |

|

| % NaCl*% NaCl |

1 |

2.02 |

2.02 |

4.90 |

0.04 |

* |

| Time: % NaCl |

1 |

0.50 |

0.50 |

2.21 |

0.17 |

|

| pH: % NaCl |

1 |

0.85 |

0.85 |

3.74 |

0.008 |

** |

| Time: pH: Temperature |

1 |

0.004 |

0.004 |

0.01 |

0.90 |

|

| Time: pH: % NaCl |

1 |

0.01 |

0.01 |

0.04 |

0.83 |

|

| Time: Temperature: % NaCl |

1 |

0.10 |

0.10 |

0.43 |

0.52 |

|

| pH: Temperature: % NaCl |

1 |

1.74 |

1.74 |

7.61 |

0.02 |

* |

| Time: pH: Temperature: % NaCl |

1 |

0.00 |

0.00 |

0.02 |

0.002 |

** |

Among the statistical tools available for the construction of a model, there are the coefficients R2 and R2 adjusted expressing the fractions of the variations of the response explained by the single model. When these coefficients tend to 1, the model is perfectly descriptive. So, with R2 = 0.998 and R2 adjusted = 0.996, it can be concluded that the model was significant with good descriptive and predictive qualities [31]. Moreover, a low coefficient variation (CV = 2.54%) has expressed the accuracy and reproducibility of the experiments. The "p-value" of the model was less than 0.0001 and the "lack of fit" (0.43), also, suggested that the experimental data obtained were suitable for the model. The results show that the chosen model confirms that the parameter that significantly influence the response is the temperature. Surface methodology was used to determine the best operating conditions to maximize the panelists acceptance to the tested products. The model can be studied by expressing the regression equation on a graph; the response of the regression equation is traced by considering any two variables and setting the other two at average levels (Figure 2).

As the temperature increased, linear increases of the panelists were observed. According to the model, the maximum response was at 6.901, obtained by considering a saline solution of the brine at pH 4.02, NaCl = 6%, temperature 40 ℃ and after two and a half weeks of natural fermentation. In Spain, and in many other countries worldwide, the common ranges of pH and temperature used during the process of natural green olives fermentations are 3.9–4.3 and 18–26 ℃, respectively. Previous works have demonstrated that β-glucosidase activity reaches its maximum at a pH close to 5 [7,32,33]; moreover, it is cultivar dependent. In fact, in Gordal cultivar, β-glucosidase activity reaches its maximum between 10 and 30 ℃, whereas between 40 and 45 ℃ in Picual and Hojiblanca cultivars [7,32]. Esterase activities are not favored by low temperatures. However, there aren't many studies on the influence of the components of the brine and storage temperatures on the enzymatic hydrolysis of oleuropein.

3.3. The influence of the technological processes on the physical-chemical and organoleptic quality of the treated olive pomaces

As described in Section 2.3, heating the olive pomaces and making some adjustments during their preparation steps, has led to the achievement of very promising results. First of all, the production of off-flavor and abnormal fermentations were reduced of 50% already after a week of fermentation resulting in a satisfactory consumer acceptance of the products (the level value of 4.61 came down to 2.12) (Table 3).

Table 3. The influence of the technological processes on the physical-chemical and organoleptic quality of the pomaces produced after one week of treatment. Sensory attributes: 1 for totally unpleasant and 9 for intensive pleasant; phenols are expressed in mg/kg. The olive pomaces were subjected to different treatments as follows: B: Olive pomace in a brine of 6% NaCl; BSM: Olive pomace in a brine of 6% NaCl synthetically modified by adding glucose (0.5%), yeast (0.01%) and lactic acid extract (0.5%); BNM: Olive pomace in a brine of 6% NaCl naturally modified by adding an old brine powder (10%); BH: Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl; BHSM: Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl synthetically modified by adding glucose (0.5%), yeast (0.01%) and lactic acid extract (0.5%); BHNM: Olive pomace heated with water vapor between 35 and 40 ℃ in a brine of 6% NaCl naturally modified by adding an old brine powder (10%). Different letters denote significant statistical differences (p < 0.05).

| Systems |

Codes |

Physico-chemical analysis |

|

Sensory analysis |

Abnormal Fermentation |

Global Acceptability |

| Acidity (%) |

pH |

Total Phenols (mg/kg) |

Smell |

Bitterness |

| 1 |

B |

0.21a |

4.9b |

1967a |

|

6.61b |

6.87b |

4.61b |

3.51a |

| 2 |

BSM |

0.25ab |

4.4a |

2325ab |

|

5.2a |

6.12a |

3.14a |

4.22ab |

| 3 |

BNM |

0.28b |

4.3a |

2612b |

|

5.77a |

5.97a |

3.21a |

5.76b |

| 4 |

BH |

0.32b |

4.4a |

2631b |

|

5.2a |

5.72a |

2.89bc |

6.72bc |

| 5 |

BHSM |

0.43c |

4.0c |

2952bc |

|

4.11c |

4.78c |

2.43c |

7.03c |

| 6 |

BHNM |

0.47c |

3.9c |

3144c |

|

3.12c |

4.29c |

2.12c |

7.12c |

Even more encouraging results have been obtained considering the preference, by the tasters, of fermented olive pomaces instead of olives treated with traditional debittering methods. In fact, the levels of bitterness were reduced up to 50% during the first week, highlighting the achievement of optimum conditions for endogenous hydrolysis enzymes to express their activity. The debittering action was mainly due to the activity of endogenous esterase and β-glucosidase enzymes (EC 3.2.1.2.1) produced by oleuropeinolytic strain such as Lactobacillus plantarum [34]. Due to the significant production of lactic acid in brines, a marked decrease in pH was registered, reaching a value of 4 in the first week. Olive pomaces in synthetically modified brines (BSM) and olive pomaces in naturally modified brines (BNM) gave very similar results. All these observations lead us to conclude that the best and natural way to control olive pomace lactic fermentation is to use older brines (10%) in order to enrich the new ones. This is, also, confirmed by the results of previous studies demonstrating that oleuropein chemical hydrolysis is favored by the acidic conditions of the brine itself [27]. In terms of free acidity, the fermented olive pomaces BH, BHSM and BHNM showed values between 0.40 and 0.43%. The fermented olive pomaces by means of traditional systems B, BSM and BNM, instead, showed values between 0.25 and 0.32%. The increase in free acidity is due to the action of lactic bacteria and yeasts fermenting sugars in organic acids [35]. Moreover, BH, BHSM and BHNM were found to be richer in phenols.

3.4. Chemical parameters of the treated olive pomaces after six month of storage

To assess the quality of the fermented olive pomaces over the time, chemical analysis were performed on olive pomace heated with water vapor between 35 and 40 ℃ before fermentation by means of a brine of 6% NaCl (BH) and olive pomace in a brine of 6% NaCl (B) after six month of storage. Indeed, a significant increase in free acidity has been observed and this could be due to the hydrolysis of triacylglycerols produced by lipolytic enzymes. In particular, the values of free fatty acids of BH and B, after six month of storage, were higher of those registered after 2.5 weeks of fermentation. In particular, the value of 0.32 and 0.21% for BH and B (Table 3), were found to be 0.80 and 1.22%, respectively (Table 4). Olive fruits after the harvest, gave a value of 0.78%. With regard to the oxidative degradation indices, peroxyde index value (PV) significantly increased during the natural debittering treatments, although the final values were relatively low (17.97 meq O2/kg oil). The observed values were lower than those reported for olives processed in California [36], and were within the limit required for extravirgin olive oil (Commission European Union, 2003). All these observations are in agreement with the results reported by Pasqualone and coworkers [37]. Concerning the total phenol content, it was observed, over the time, a decrease in its concentration. In particular, the phenols concentration values of 2612 and 1967 mg/kg for BH and B (Table 3) were found to be 256 and 187 mg/kg, respectively (Table 4). Olive fruits gave a value of 287 mg/kg (Table 4). Moreover, the levels of primary oxidation were found relatively low: 1.987 and 2.89 for BH and B, respectively. In fact, the extent of primary oxidation was limited, as demonstrated by the low PV levels, making the secondary oxidation very low. All these results pointed out the high quality of the fermented products obtained by establishing the best working parameters.

Table 4. Chemical parameters of olives fermented olive pomaces after 6 month of storage. BH: Olive pomace heated with water vapor between 35 and 40 ℃ before fermentation by means of a brine of 6% NaCl after 6 month; B: Olive pomace in a brine of 6% NaCl after 6 month. Different letters denote significant statistical differences (p < 0.05).

| Sample |

K232 |

K270 |

Free fatty acids (%) |

Peroxyde index (meq O2/kg oil) |

Total phenols (mg/kg) |

| Olives at harvest |

1.972a |

0.332a |

0.78a |

8.98a |

287a |

| BH |

1.987a |

0.342a |

0.80a |

10.76b |

256a |

| B |

2.89b |

0.765b |

1.22b |

17.98c |

187b |

4. Conclusion

The fermentation of olive drupes is a spontaneous and complex process in which many chemical-physical parameters, such as temperature, pH, salt concentration, fermentable sugars, content and nature of phenols and other microbiological agents play a very important role for the success of the process and for the quality of the final products. As there are very few researches dealing with the direct debittering of olive pomaces after the oil extraction, this work has focused on developing mechanical strategies to improve the nutritional and sensory quality of this olive by-product by modulating endogenous enzymatic activity. The purpose of this research was, in fact, the investigation of a natural fermentation process, analogous to the one performed for the production of table olives, to apply to olive pomaces in order to find the optimal conditions for obtaining a final product for human consumption with important nutritional values. The aim of this research was, therefore, to establish the best working parameters for the obtainment of a favorable environment to promote the development of the oleuropeinolytic strain and the activation of oleuropein hydrolysis enzymes.

Acknowledgements

This work was financially supported by the National School of Engineering from the University of Sfax as part of a fellowship under the project "VALORIZATION OF BIOMASS". The authors wish to thank Prof. Mohamed AYADI (Olive Tree Institute, University of Sfax) for his support in training sessions on sensory analysis, the company "KAPOUDIA OLIVE OIL" for providing the samples and the Research Center for Olives, Citrus and Tree Fruit of Rende (CS) for technical assistance and encouragement during the fellowship.

Conflict of interest

The authors declare no conflict of interest that would prejudice the impartiality of this scientific work.

DownLoad:

DownLoad: