Quality degradation due to inappropriate postharvest handling, including short exposure to high and variable temperature environments and cooling delay, is a critical issue for maintaining the freshness of vegetables and fruits in further marketing chains and final consumption. The goal of this research was to explore the influence of delayed cooling treatments on key quality attributes of tomatoes such as fresh weight, total soluble solids (TSS), firmness, and skin color (L*, a*, and a*/b*). Three treatments were applied to freshly harvested tomatoes: immediate storage (IS) after harvest, delayed cooling (DS) leaving tomatoes without cover for one day, and under cover (DSC) separately in a greenhouse and then storage in a controlled chamber at a temperature of 10 ± 1 ℃ and relative humidity of 90 ± 3%. The quality attributes of the stored tomatoes were examined for 15 storage days at 5-day intervals to examine the effects of cooling delay on the postharvest quality of tomatoes stored in a controlled chamber. After 15 days of storage, tomatoes that underwent the three treatments exhibited a progressive weight loss of 1.41%, 1.86%, and 1.69% for the IS, DS, and DSC treatments, respectively. Slower firmness reduction (31.2%) was observed for tomatoes with the IS treatment than for those with the other treatments over the storage duration. During the storage time, tomatoes that experienced the DS treatment exhibited higher increases in TSS (°Bx) values (4.79 to 5.76) than other tomato samples. Smaller changes in color values (L*, a*, and a*/b*) were observed for IS-treated tomatoes. During the storage time, overall changes were slower for IS-treated tomato samples than for those with other treatments. The results of this research indicate that the accumulation of field heat due to cooling delay could decrease the overall quality attributes of tomatoes in the market chain. The immediate transfer of harvested tomatoes to a cool temperature is strongly recommended.

1.

Introduction

Tomato (Solanum lycopersicum L.) is one of the most extensively consumed fruit-vegetables in the world and has been considered an important source of nutrition, with carotenoids (mainly lycopene and β-carotene), fibers, and vitamins [1,2]. Consuming carotenoids from tomatoes is associated with a reduction in the risk of cancer and incidence of heart diseases [3,4]. Fresh commodities should meet consumer needs, and postharvest handling can have a dramatic effect on quality and shelf life; therefore, appropriate postharvest handling is required [5,6,7]. Tomatoes are sensitive products that are highly perishable due to abnormal treatment, impact loads and vibrations during transportation, storage and marketing processes [8]. In particular, the postharvest storage environment is critical for maintaining the quality of tomatoes in further marketing chains and consumption. Maintaining favorable temperature and humidity is critical to lower the postharvest losses of tomatoes [9]. An important example of improper postharvest handling of fresh produce after harvest includes delays in cooling, resulting in overall quality loss during processing and storage.

Temperature greatly influences the respiration rate, and low temperature is a major environmental factor in maintaining the postharvest characteristics of fruits and vegetables [10,11]. Mature green tomatoes should be stored at approximately 10–13 ℃ to avoid chilling injury, which may be detrimental to flavor quality [12,13]. Tomatoes do not tolerate extremely low temperatures below 10 ℃, while high temperature can accelerate the respiration rate [14]. In contrast, harvested vegetables and fruits maintain their freshness, appearance, nutritive value, and shelf life at very high humidity. The optimal relative humidities for mature green and firmer ripe tomatoes are within the ranges of 85–95% and 90–95%, respectively [15]. Tomatoes stored at a lower humidity can lead to shriveling, whereas completely saturated atmospheres may stimulate mold and fungal development [16].

Reducing postharvest losses remains a major goal, mainly due to food security issues that need to be rectified worldwide, especially in developing countries [17,18]. Postharvest losses of fresh fruit in developing countries are approximately 20–50% [19]. Despite the numerous benefits of tomatoes, postharvest losses make tomato production unprofitable, and these losses may occur during the harvest period, transportation, processing or storage [20]. Postharvest handling has some influence on the postharvest quality deterioration of tomatoes. Several studies have reported on the shelf life and postharvest storage of tomatoes. Many studies have dealt with extending the shelf life and storage period of tomatoes under various treatments and storage conditions. Farmers conventionally leave harvested tomatoes in greenhouses for approximately half a day or one day before transportation to storage and processing centers. There is not much information available in the literature regarding the influence of short cooling delays on the attributes of harvested tomatoes. Hence, it is crucial to investigate the effect of cooling delay on the postharvest attributes of tomatoes.

Color, firmness, weight, and total soluble solids (TSS) are essential quality aspects of tomatoes affected by postharvest handling, storage conditions, and enzymatic activity [21,22]. These quality indices influence market success and consumer acceptance and could be retained through proper postharvest handling techniques [23]. Applying appropriate postharvest management techniques for the reduction of the postharvest losses of tomatoes would be of great importance to farmers, traders, and consumers [24]. Moreover, data on the postharvest attributes of fruits and vegetables are important because they are required as input for models to predict postharvest attributes and behavior [25]. Therefore, this research was performed to explore the influence of a short-term (24 h) cooling delay on the postharvest quality attributes, such as weight, TSS, firmness, and color values (L*, a*, and a*/b*), of tomatoes stored in a controlled chamber.

2.

Materials and methods

2.1. Tomato samples and treatments

“Dabol” variety tomatoes with an average width and height of 8 ± 1.2 cm and 5 ± 0.2 cm, respectively, were grown in the middle region of the Republic of Korea and immediately transported from the field to storage facilities. We used three treatments, which were “immediate storage of tomatoes after harvest (IS)” in a controlled chamber (i.e., without any cooling delay), storage in the controlled chamber after “delayed storage leaving tomatoes for one day (DS)” in a greenhouse, and storage in the controlled chamber after “delayed storage leaving tomatoes under cover for one day (DSC) with a greenhouse shade cloth of 1.0 mm thickness” in a greenhouse (i.e., delayed cooling treatment for 24 h).

The storage treatments were conducted in separate places in the greenhouse and controlled chamber with dimensions of 7.5 m × 5.5 m × 3.5 m and 6.5 m × 4.5 m × 3.0 m, respectively. One group of tomato samples was stored inside the controlled chamber on harvest day (day 0), and the other two groups of tomato samples were put separately inside the greenhouse with and without cover on the same day. During the delayed cooling of tomatoes in the greenhouse for 24 h, sensor nodes consisting of temperature and humidity sensors (AM2315, Aosong Electronics Co., Ltd., Guangzhou, China) were placed inside the greenhouse, outside of the greenhouse, and in the covered and uncovered tomato storage boxes. The temperature and humidity conditions were continuously observed inside the greenhouse and controlled chamber during the delayed cooling period. The temperature and humidity inside the controlled chamber were maintained at 10 ± 1 ℃ and 90 ± 3%, respectively.

During the 24 h of delayed cooling of tomatoes, the outside temperature and humidity for the greenhouse were 18–28 ℃ and 55–75%, respectively, while the temperature and humidity inside the greenhouse were 28–38 ℃ and 60–85%, respectively. The temperature and humidity inside the tomato box with a cover were 26–36 ℃ and 65–85%, respectively, and those inside the tomato box without a cover were 29–39 ℃ and 60–80%, respectively, during the 24 h of delayed cooling inside the greenhouse.

The quality attributes of the tomato fruits were measured on day 0, and the tomatoes were put in the three storage conditions immediately. After the 24-h cooling delay, the tomato fruits treated with and without a cover inside the greenhouse were restored in the controlled chamber. Thereafter, all tomato fruits were continuously stored in the controlled chamber, and the quality attributes of the stored tomato samples were assessed for 15 storage days at 5-day intervals.

2.2. Experimental design and statistical analysis

The tomato samples were allocated to the three treatments, and 30 fruit samples with three replications were taken for each storage treatment. Consequently, there were 90 fruits for each storage treatment, and 360 tomato samples were evaluated under these treatments after 0, 5, 10, and 15 days of storage. The quality attribute data were subjected to analysis of variance (ANOVA) following a completely randomized design with SAS software (version 9; SAS Corporation, Cary, NC, USA). The data were analyzed by considering storage treatments, replication, the storage period, and observations as factors in the statistical analysis. Comparisons among the means were performed by Duncan’s multiple range tests with significance at the 5% level of significance.

Regression analyses were performed to describe the changes in the quality attributes of the stored tomatoes treated with the three treatments. In the mathematical equations, the quality attributes were treated as dependent variables, and tomatoes treated with different storage treatments were treated as independent variables. Linear and various nonlinear regressions, such as exponential (ex), logarithmic (ln(x)), polynomial (P(x)), and power (kxn), were employed to describe the changes in the quality attributes of the stored tomatoes, and the significance level of each equation was also identified. The values of the coefficient of determination (R2) were considered to choose the best-fitting model for describing the quality changes throughout the storage time.

2.3. Measurement of quality attributes

2.3.1. Weight loss

To determine the weight loss of the tomato samples, the difference between the initial weight and final weight of a tested tomato divided by the initial weight was considered [26]. The weight loss was assessed by weighing individual tomatoes at the beginning of the experiment and after placing them into each storage treatment. After the initial weighing on day 0, the tomatoes were put into the three storage conditions and weighed after 5, 10, and 15 storage days. The weight loss of the tomato samples was expressed as a cumulated percentage of weight loss from the initial weight.

2.3.2. Firmness

Fruit firmness is one of the most relevant properties among the quality attributes and could be considered a final quality index during the purchase of fresh tomatoes [27]. The firmness of the tomatoes was measured by a penetrometer (TMS-Pro, Food Technology Corporation, Sterling, Virginia, USA). Following the procedure of Choi et al. [28], the tomatoes were compressed by the probe at a penetration depth of 5 mm and at a speed of 50 mm/min using a conical plate.

2.3.3. Total soluble solids (TSS)

Tomato fruits were taken randomly and wrapped with four layers of cheesecloth. A juice extractor (FruX80, Goojung Engineering Co. Ltd., Seoul, Korea) was used for extracting juice, and the TSS content was measured using a digital refractometer (PR-32a, Atago Co. Ltd., Tokyo, Japan). The results were expressed in Brix (°Bx).

2.3.4. Color

Tomato color determines the degree of consumer acceptance. The color values (L*,

a*, and b*) of tomatoes were measured using a colorimeter (CR-400; Konica Minolta Inc., Tokyo, Japan) equipped with illuminant D65 and an 8 mm aperture for illumination and measurement. The calorimeter was calibrated with a white standard (L* = 93.9, a*

= 0.31, b* = 0.32) before the color measurement. The L* value represents lightness (L* = 0 for black, L* = 100 for white); a* represents intensity in red-green (a*

> 0 for red, a* < 0 for green); b* represents intensity in blue-yellow (b* > 0 for yellow, b* < 0 for blue); and the a*/b* value is the ratio of the red-to-green component of color that represents the color index that better relates to color variation during tomato ripening [29].

3.

Results and discussion

3.1. Weight loss

In general, the weight loss of a stored tomato increases progressively throughout the storage time and continues until the fruit attains a fully ripe condition [17] and is used to describe the fruit quality due to its impact on crispness [30]. In this study, the weight loss increased during the storage time for all treated tomatoes stored in the three different treatments. The DS and DSC treatments showed similar weight loss after 5 and 10 days, but tomatoes that underwent DS treatment showed slightly higher weight loss after 15 days of storage. However, the weight loss of the IS-treated tomatoes was found to be the lowest (1.42%) compared with those of the DSC-(1.69%) and DS (1.86%)-treated tomatoes by the end of the storage time.

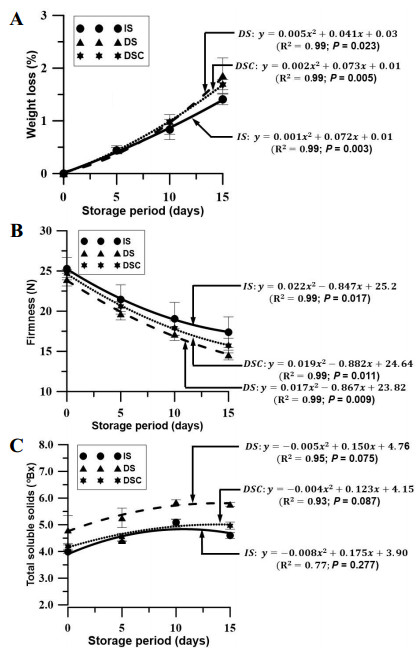

The analysis of variance (ANOVA) of the quality attributes with the three different treatments and storage time as factors is shown in Table 1. Significant (p < 0.05) changes in the quality attributes of tomatoes among the delayed cooling treatments and between the storage times are shown in Table 2 and Table 3. The statistical analysis shows that the influence of the delayed cooling treatments on the weight loss of tomato fruits over the storage time was significant (p < 0.05). The weight loss of tomatoes was also significantly affected (p < 0.001) by the period of storage. The coefficient of variation (CV) and R2 values for the weight loss were found to be low. Polynomial models were fitted for predicting the weight loss of tomato fruits during the storage period with R2 values of 0.99 for the IS-, DS-, and DSC-treated fruits (Figure 1A).

Similar results were reported by Žnidarčič et al. [31] after tomato storage periods of 14 and 28 days at 10 ℃ and 80–85% relative humidity. A weight loss of 3.76% was reported by Guillén et al. [32] during storage of tomatoes at 10 ℃ for 7 days and a further 4 days at 20 ℃ for a shelf-life period. Moneruzzaman et al. [33] reported a weight loss of 11.96% irrespective of the maturity stage on the 12th day of storage for fully ripe tomatoes, while storing the tomatoes in an uncovered condition, covered with polyethylene and placing CaC2+ polyethylene below the tomatoes and then covering them with polyethylene. Roberts et al. [12] reported a weight loss of grape tomatoes of 4.1% after storing the tomatoes for 7 days at 10 ℃ and transferring them to 20 ℃ for ripening for another 10 days. Li et al. [34] reported a weight loss of less than 2% for tomatoes after delayed cooling for 24 h at 6 ℃, 22 ℃, and no cooling conditions and storage afterward for 3 days at 22 ℃ and 3 days at 6℃, which is in agreement with the present findings. This weight loss could be from respiration and diffusion through the surface of the tomatoes, leading to a deterioration in quality [35].

3.2. Firmness

The tomatoes stored with the IS, DS, and DSC treatments experienced a reduction in firmness over the 15-day storage period. The firmness of the tomatoes varied significantly (p < 0.05) over the storage treatments (Table 1). The CV and R2 values for changes in firmness indicate the goodness of fit of the model, and the coefficient of variation of the variable was found to be low. Even though significant differences (p < 0.001) in firmness losses were found among all treated tomatoes during the storage time, slower firmness losses were observed in IS-treated tomato samples (31.2%) than in DS- (39.2%) and DSC (36.3%)-treated tomato fruits after the storage time (Table 2). The results of this study indicate that immediate storage of tomatoes after harvesting could maintain tomato firmness better than delayed cooling of tomatoes. Polynomial models fitted the data of firmness changes over the storage duration for the IS-, DS-, and DSC-treated tomatoes with an R2 value of 0.99 (Figure 1B).

During the storage period, the decrease in the firmness of the tomato samples could be because of the physiological breakdown of the fruit cell walls [36]. Lana et al. [37] found that the firmness of tomatoes decreased during storage. Guillén et al. [32] found a typical softening process in control tomatoes, with a reduction of 54% from the firmness levels at harvest (5.29 ± 0.24 N mm−1) after 7 days at 10 ℃, which is in agreement with the present findings. Tolesa and Workneh [9] reported a decline in the firmness of tomato fruits harvested at the pink, green, and red maturity stages from 25 to 13 N, 29 to 10 N, and 20.5 to 10 N, respectively, over a storage period of 21 days inside an evaporative cooler. Majidi et al. [38] reported that controlled atmosphere storage maintained tomato firmness better than cold storage during the first 10 storage days, and a steeper decline in firmness (65 N to 59 N) was observed from 10 to 20 days of storage.

3.3. Total soluble solids (TSS)

The general trend observed during storage for all treated tomatoes was an initial increase in TSS values at 10 days of storage, followed by a decrease at 15 days of storage, which may be due to the ripening conditions of the tomatoes (Figure 1C). Significant differences (p < 0.05) in TSS values were observed among all delayed cooling-treated tomatoes, and highly significant differences were also found over the storage period (Table 1). However, minimum changes in the TSS values (3.98 to 4.60) were found in the tomatoes that underwent IS treatment, and the highest changes (4.79 to 5.76) were observed for tomatoes that underwent DS throughout the storage period (Table 2). The DSC-treated tomatoes showed slower changes in TSS values than those that underwent DS, which may be a result of the effect of the cover lowering the temperature inside the tomato box [39]. Polynomial models were found to be the best fit for predicting the changes in TSS content of the treated tomato samples, with R2 values of 0.77, 0.95, and 0.93 for IS-, DS-, and DSC-treated tomatoes, respectively (Figure 1C).

A similar trend was observed by Tigist et al. [40] while storing some fresh and processed tomato varieties at a room temperature of 15.4 ℃ to 16.2 ℃ and a humidity of 34.8% to 52.4%. Majidi et al. [41] found that the minimum changes in TSS values in controlled atmosphere storage increased from 5.20 to 5.59 and then decreased to 5.18 after storage for 90 days, where the highest TSS value was 5.7 during 20 days of storage. Tolesa and Workneh [9] found that the TSS of tomatoes harvested at the pink mature and green stages increased from 3.7–4.5% and 3.9–4.2%, respectively, over 7 days of storage, followed by an increase after 14 storage days, with a decreasing trend thereafter, which is in agreement with our findings. Among qualitative properties, soluble solids content has been correlated with quality deterioration during postharvest storage of tomatoes and can influence acceptability by consumers [42,43]. The recommended range of TSS values suitable for the processing industry is 5.5 to 8.5% [44]. Previous studies reported that TSS in medium-sized fruit ranged from 5 to 7% and in large beefsteak tomatoes ranged from 3 to 5% [45,46,47].

3.4. Color

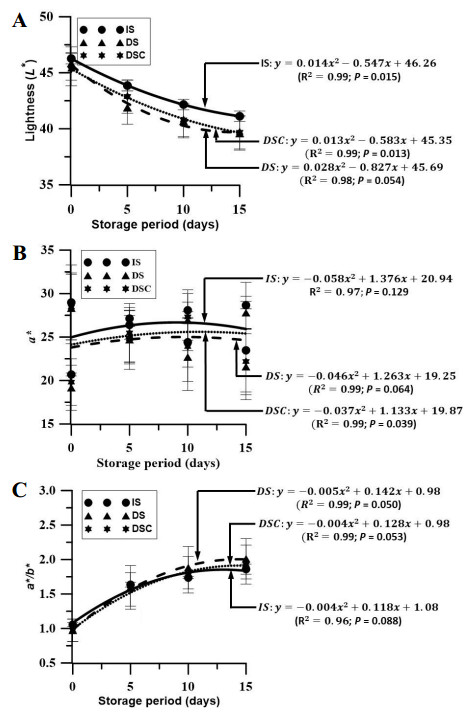

The changes in the color attributes (L*, a*, a*/b*) of tomatoes during storage under the three different treatments are presented in Figure 2. A general degradation of tomato skin color was observed throughout the storage duration. Significant differences (p < 0.05) in the L* values of the tomato samples were observed between storage treatments (Table 1). However, no significant changes were found for the a* and a*/b* values between the delayed cooling treatments. However, significant changes (p < 0.001) in the L*, a*, and a*/b* values of tomatoes were observed over the storage period. The lowest changes in L* (46.3–41.1) of the tomato samples were found for IS-treated tomato samples, which showed less browning than the delayed cooling-treated tomato fruits. During the storage period, lower changes in the a* value (20.7–28.6) and a*/b* ratios (1.05–1.86) occurred for IS-treated tomatoes than for DS- and DSC-treated fruits (Table 3). The changes in the L*, a*, and a*/b* attributes of tomato fruits treated under the three treatments over the storage period were also analyzed by various regression methods. Polynomials were found to be the best equations for predicting the changes in L* values throughout the storage duration, with R2 values of 0.99, 0.98, and 0.99 for IS-, DS-, and DSC-treated tomato fruits, respectively (Figure 2A). The changes in a* values were well fitted by polynomial models with R2 values of 0.97, 0.99, and 0.99 for IS-, DS-, and DSC-treated tomatoes, respectively (Figure 2B), and the changes in a*/b* ratios throughout the storage time were found to be best fitted with R2 values of 0.96, 0.99, and 0.99 for IS-, DS-, and DSC-treated tomato samples, respectively (Figure 2C).

Similar results were obtained by Khairi et al. [29], who reported that the lightness (L*) values of tomatoes under water stress and no water stress decreased during storage at 10 ℃ and that a*/b* ratios increased after 16 days of storage. Guillén et al. [32] reported an increase in color a* values in some tomato cultivars at two ripening stages while stored at 10 ℃ for 28 days. Pinheiro et al. [30] also found an increase in the a* value during 30 days of storage and recommended a storage temperature of 10 ℃ to better preserve tomato quality, avoid chilling injuries and extend shelf life. The change in color of tomatoes is correlated with the ripening process [48] and is one of the indications of the physicochemical development stages of tomatoes [40]. Campbell et al. [49] reported that during the normal ripening of tomatoes, tissue color changes from green to orange and red. Majidi et al. [38] observed slower redness changes for tomato fruits stored in controlled storage than for those stored in cold storage during the first 30 days of storage.

4.

Conclusion

Tomatoes are one of the most valuable fruits in the domestic and foreign markets. Optimum postharvest handling from harvest to field storage significantly affects the freshness of tomatoes in the following marketing procedures, including long-term storage and transportation. It is important for the freshness of tomatoes to be maintained during storage and transportation. Even the quality of processed products is affected by their postharvest handling procedures. We examined the influence of proper postharvest management in the field on changes in quality in the following marketing. Growers put their tomatoes in the working space of greenhouses 1 to 2 days after harvest with or without shade. This procedure seems to stimulate the deterioration of fruit quality, resulting in faster weight loss and color changes than those of tomatoes handled with temperature and humidity adjustment.

In short, the effects of cooling delay on the postharvest quality of tomato fruits, such as weight loss, TSS content, firmness, and color values (L*, a*, and a*/b*), were evaluated in this study. Different delayed cooling treatments affected the weight loss, firmness, TSS content, and color attributes. A general decrease in weight and firmness was observed in all the treatments, while the changes were slower in the immediate storage treatment than in the other delayed cooling treatments after 15 days of storage. The TSS contents of the tomatoes stored under the three different treatments were found to be higher on the 10th day of storage than on harvest day, but the IS treatment showed a lower rate of increase in TSS content over the storage period. The IS-treated tomato samples showed lower changes in color attributes (L*, a*, and a*/b*) after the storage time than the other treated samples. The overall degradation of the evaluated quality attributes of the treated tomatoes was slower for IS-treated fruits, and due to the cover effects, DSC-treated samples remained in better condition than DS-treated tomatoes. The results of this study indicate the importance of postharvest handling for the quality attributes of tomatoes, so tomato growers should properly handle harvested tomatoes before transportation to storage and processing centers.

Acknowledgments

This work was supported by the Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) through the Agriculture, Food and Rural Affairs Convergence Technologies Program for Educating Creative Global Leaders, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) (Project No. 320001-4), Republic of Korea.

Conflicts of interest

All authors declare no conflicts of interest in this paper.

DownLoad:

DownLoad: