Supplementation of agricultural soil with biochar can positively affect growth and yield of crop plants. In this study, a mixture of different amounts of rice husk biochar (RHB) at 1.5%, 2.0% or 2.5% by weight (wt.%) and 20 wt.% vermicompost were used to grow Chinese kale in a soil on a high rise building in Bangkok city. The effect of this mixture on yields of Chinese kale and the level of carbon storage in the soil and plants were evaluated, since this could contribute towards urban food security and reduce greenhouse gas emissions. Eight treatments were evaluated as (i) the soil alone (TC), and soil supplemented with (ii) 20 wt.% vermicompost (TM20), (iii–v) RHB (TB1.5, TB2.0 and TB2.5), or (vi–viii) vermicompost with RHB (TMB1.5, TMB2.0 and TMB2.5). Treatment TMB2.0 gave the highest yield of Chinese kale shoots, followed by TMB2.5, TM20 and TMB1.5, respectively. In addition, TMB2.5 gave the highest carbon storage in the soil plus plants, followed by TMB20, TM20 and TMB1.5. Thus, adding the appropriate amount of RHB and vermicompost mixture in the soil led to a higher yield of plant products, including an increased level of soil carbon storage. Applying RHB in urbanized agricultural areas is an alternative way for metropolitan areas to boost the yields of crop plants for food sustainability and long-term urbanized environmental management.

1.

Introduction

Biochar is a solid compound principally comprising carbon bonded to form aromatic structures and connected with hydroxyl and carboxyl groups [1], making it a highly stable material [2]. Biochar is not easily decomposed [3,4] and can endure in the soil for a long time. Biochar is produced by pyrolysis of organic matter at temperatures ranging from 350–700 ℃

[5,6,7,8]. The most important factors controlling the quality of biochar are the feedstock and production process. The key produiton variables are temperature and duration of heating [9,10]. Typical feedstocks used are crop residues such as rice husks, wood scrapings, animal droppings, cassava rhizomes or nutshells [11,12,13].

The main aim of applying biochar to agricultural soils is to boost crop yield and improve the long-term physical, chemical and biological properties of the soil. Previous research has established the effectiveness of soil augmentation with biochar [6,11,14], and its value in mitigating the leaching of fertilizers into the environment as a result of overuse [15]. The use of biochar in agriculture can also contribute to improving farmer health, reduce crop production costs and increase farmer incomes [16]. In addition, biochar can significantly reducing greenhouse gas emissions by reducing release of carbon dioxide (CO2) through carbon sequestration [5,11,13]. This is because biochar is carbon-stable and can 'lock up' the carbon into long-term storage in the soil [17,18]. Meanwhile, enhanced growth and biomass of the crop, induced by soil augmentation with biochar, contributes to additional indirect carbon storage [11].

In many agricultural countries in Asia, large volumes of rice husk are produced as waste every year [19]. The use of rice husk as a feedstock for biochar production is therefore of interest for use as a soil amendment, with potential environmental, production and economic benefits. Smallholders in countries including China, Lao PDR and Vietnam, among others, have successfully adopted this approach. However, in Thailand, production of biochar from rice husk is not commonly practiced.

Even though research has confirmed the effectiveness of biochar in retaining soil carbon, thus enhancing agricultural productivity and improving soil health, several practical limitations constrain its utility, especially for poor farmers in developing countries. Constraints include a lack of a standard production method to produce quality biochar, high cost, and cost-effectiveness. Several investigations of the cost effectiveness of biochar from rice husk e.g., [20,21,22,23,24,25] report that biochar is cost effective in the long run, providing a range of environmental benefits by retaining carbon in the soil, reducing emission of greenhouse gases [5,11,13], improving soil health and reducing the need for expensive chemical fertilizers [12]. In many countries, biochar is sold in the market at prices as low as $12 per mg [21]. Nevertheless, this is beyond the reach of many poor farmers, who prefer to produce biochar themselves. Sriburi and Wijitkosum [8] designed a low-cost biochar kiln to produce biochar in rural Thailand, using locally-available materials. The kiln produces biochar at low cost and the production process is not too complicated. Moreover, biochar kilns are inexpensive (approximately 50 USD) producing sufficient amount of high-quality biochar for agricultural use [12]. For the radish cultivation in the 1600 sq km experimental plot, the cost of biochar including kiln production was 12 USD per crop cycle. The total cost for the radish cultivation was 578 USD. However, incorporating biochar with cow manure increased the yield by 58% in comparison to the treatment that only incorporated cow manure. The increased percentage generated profits for farmers at approximately 1200–1293 USD per 1600 sq m [25].

The rapid global expansion of urbanization drives increasing demand for food in urban areas, increasing pressure on rural areas surrounding big cities, e.g., Tokyo, Beijing, Singapore, Hong Kong and Bangkok. The impacts of climate change on food security make it necessary to seek unconventional ways of producing our food. Urban food production has emerged as one such solution. Urban food production can support ecological and cultural functions, referred to as multi-functionalized agricultural land [26]. Smit et al. (2001) [27] stated that urban agriculture has the potential to help address food and climate problems associated with urbanization, where using the rooftops of buildings for urban agriculture offers an alternative strategy to contribute to sustainable urban development planning [28,29]. Moreover, rooftop agriculture in urban areas would reduce the building's temperature and local micro-climate, reduce air, noise and CO2 pollution [29], as well as reduce the urban heat island effect [30].

This study investigated the effect of soil augmentation with rice husk biochar (RHB) as a model sustainable agricultural biochar, on growth of Chinese kale as a model food crop, cultivated on the rooftop of a high rise building in Bangkok. The effect of augmentation on yield of plant biomass and carbon storage in the plant and soil was measured.

2.

Materials and Methods

2.1. Experimental design

The experimental setup for the different treatments was based upon a complete randomized design. The eight treatments were comprised of (ⅰ) soil alone as an untreated control (TC); soil supplemented with (ⅱ) 20% by weight (wt.%) of vermicompost (TM20), or (ⅲ–ⅴ) RHB at 1.5 wt.%, 2.0 wt.% or 2.5 wt.% (TB1.5, TB2.0 and TB2.5, respectively), or (ⅵ–ⅷ) 20 wt.% vermicompost with RHB at 1.5 wt.%, 2.0 wt.% or 2.5 wt.% (TMB1.5, TMB2.0 and TMB2.5, respectively). Each treatment had four replications. Chinese kale was planted in wooden plots of 0.3 × 0.8 × 0.3 m (width × length × depth) on the rooftop (14th floor) of Chula Unisearch building, located in the heart of Bangkok.

2.2. Analysis of the planting materials

2.2.1. Soil analyses

The soil used in the experiment was analysed for its physical and chemical qualities in terms of soil texture (hydrometer), pH (pH meter with 1:1 (v/v) soil: Water), electrical conductivity (EC; EC meter with 1:5 (v/v) soil: Water), cation exchange capacity (CEC; ammonium acetate method), bulk density (core method), wet oxidation (Walkley and Black method), total nitrogen (Total N; Kjeldahl method), available phosphorus (Bray II method), exchangeable potassium, calcium and magnesium (saturated NH4OAc extraction and atomic absorption spectrophotometry; AAS).

2.2.2. Biochar analyses

The biochar used in this study was produced from rice husk in a controlled temperature Rice Husk Biochar retort for slow pyrolysis process (patent number 1601001281) at 400–500 ℃. At this temperature range the dried rice husk formed a high-quality biochar. The RHB was analysed for its surface area and pore size using a surface area analyser using the Brunauer-Emmett-Teller method of analysis of the nitrogen adsorption isotherms. Total carbon (Total C) and total organic carbon (TOC) content were measured using a TOC analyser (Shimadzu TOC Tcvh) using the combustion-infrared method, while the carbon, hydrogen, nitrogen and sulfur atom contents (wt.%) were measured using a Carbon, Hydrogen Nitrogen and Sulfur/Oxygen Analyzer (Leco CHN628 model). The oxygen content was calculated from the residual difference of the biomass. In addition, the pH (pH meter with 1:2 (v/v) char: Water), EC (EC meter with 1:5 (v/v) char: Water), CEC (leaching method), organic matter (OM; Walkley and Black method), Total N (Kjeldahl method), P2O5 (vanadomolybdophosphoric acid colorimetric method) and total K2O (AAS) were measured.

The RHB yields from Controlled Temperature Rice Husk Biochar Retort for Slow Pyrolysis Process was 45% of the total feedstock, representing a conversion ratio of feedstock (rice husk) to biochar yield of 1:0.45 (88 kg:40 kg).

2.2.3. Vermicompost analyses

The fertilizer used in this study is vermicompost, produced from the earthworm Eudrilus eugeniae, the most appropriate species for tropical areas [31]. To produce vermicompost, earthworms are fed dairy cattle dung, that had been pre-immersed in water for 2–3 days to cool it down and increase the moisture content. Earthworms can also be raised indoors in an open-topped rearing bucket with a diameter of 50 centimeters and height of 20 centimeters. Each bucket should contain 3,000 grams of dairy cattle dung per 300 grams of earthworms. No additional nutrients or supplements are added during the process. Humidity must be controlled by daily watering once per day with 0.5 liters water per bucket to prevent drying out and solidity. Humidity levels are controlled at 60–80% to optimize growth conditions. The process may take from 20–45 days, depending on the amount of food given. To collect the final vermicompost, a filter is used to separate the earthworms from the vermicompost which is then ready for use in the experiment.

Key chemical parameters were analysed, including pH, EC, CEC, OM, Total N, P2O5 and Total K2O using the same methods as for the biochar analyses (section 2.2.2. Biochar analyses).

2.2.4. Sample collection and product analysis

Chinese kale plants were harvested when fully grown at 49 days after planting. The whole plants were collected and separated (roots, stem and leaves). The plant yield was calculated from only the shoots (stem, stalks and leaves), as only these parts are consumed by humans. Carbon storage in the form of the Chinese kale biomass was calculated from the complete biomass (roots, stem, stalks and leaves) by random sampling of plants from each plot of each experiment. Plants were carefully removed making sure that all parts were intact. They were then cleaned, weighed (wet weight) and dried in an oven at 75 ℃ until they reached constant weight (ca. 48 h) and reweighed (dry weight). The relative humidity (%) was then derived from Eq 1 [32,33]; then, the moisture content was calculated to find biomass or dry weight in each part of the plant were derived from Eqs 1–3, and compared with the carbon distribution in each part of the plant and carbon storage as biomass [34].

2.2.5. Sample collection and product analysis

Carbon storage in the soil used for planting was calculated from soil organic carbon x bulk density (BD) as reported [35,36] using Eq 4. Soil collected at a 0–15 cm depth was used for calculating the BD since carbon storage in the soil was deposited in the top soil.

where CSoil is the carbon storage (ton/ha), C is the carbon concentration of the mineral soil (wt.%), S and BD are the area (ha) and bulk density of the soil (g/cm3), respectively, and d is the depth of the measured soil layer (cm).

2.3. Statistical analysis

Data were displayed as the mean ± standard deviation (SD), derived from four replicates. Turkey's multiple comparison test was used to analyse the mean variance and compare the significance of the difference between means using the Statistical Package of the Social Science (SPSS) software.

3.

Results

3.1. Principal composition of the planting material analysis

The soil analyses revealed that the soils were mainly clay, slightly alkaline with a moderate EC, CEC and OM level (Table 1). The main plant nutrients in the soil were fairly low, with total N content of 0.16 wt.%, available P of 15.0 mg/kg and exchangeable K of 207.0 mg/kg.

The RHB had a high surface area (41.43 m2/g) and pore density (0.034 cm3/g) and was less alkaline than the soil with a low EC and CEC. The composition of the RHB contained a Total C level of 47.67 wt.% which was essentially total organic carbon. The results showed that the amount of Total C was equal to TOC which indicated that rice husk biochar contained solely organic carbon. Other properties of rice husk biochar included N (1.06%), H (2.22%), Ash (20.18%) and O (28.87%). Its O/C molar was 0.45 and H/C molar was 0.27. The carbon compounds of the RHB are highly stable with low H and N content and low O/Corg and H/Corg molar ratios. These ratios indicated that the RHB was of high quality and suitable for use as a soil amendment and soil carbon storage. In terms of its nutritional value, it had a higher Total N content than the soil, with Total P2O5 and K2O content of 0.29 wt.% and 1.02 wt.%, respectively, with a high OM content of 13.06 wt.% (Table 1). The vermicompost was slightly acidic with a moderate CEC, low EC and high level of OM, Total N, Total P2O5 and Total K2O nutrients (Table 1).

3.2. Chinese kale productivity

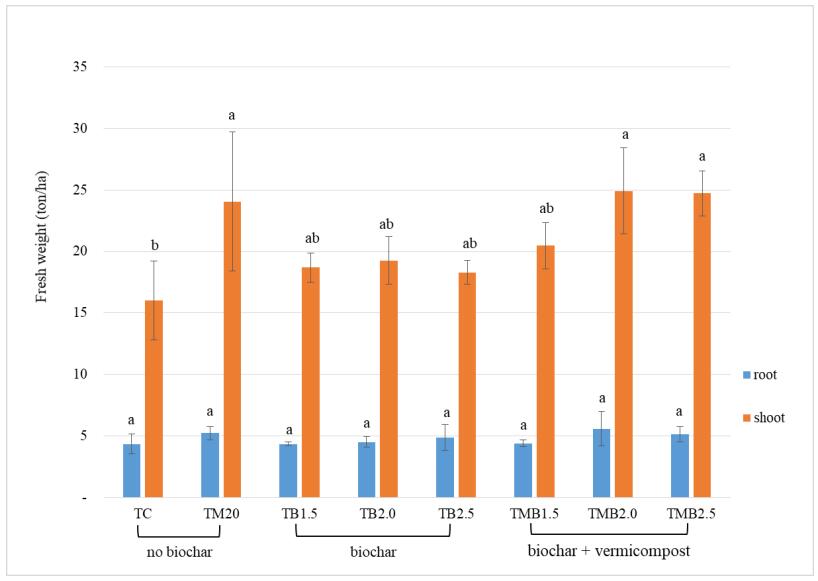

The highest wet weight of stem, stalks and leaves was found in treatment TMB2.0 (24.93 ton/ha), followed by TMB2.5 (24.73 ton/ha), TM20 (24.07 ton/ha) and TMB1.5 (20.48 ton/ha). Thus, the addition of 20 wt.% vermicompost alone (TM20) or with RHB (TMB1.5, TMB2.0 and TMB2.5) significantly increased the yield of Chinese kale (P < 0.05) compared to soil alone (TC). With respect to the mixed vermicompost and RHB, crop yields increased with increasing levels of RHB, whereas when RHB was added to the soil alone, no significant differences in yield were observed between each pure biochar treatment. The results were due to the fact that Chinese kale grew well in alkaline soil with pH between 5.5 and 6.68. The alkaline RHB increased soil pH to 8.10 in pure biochar-treated treatments in comparison to treatments with vermicompost (pH 7.4). Moreover, Chinese kale needed a high amount of N. The amount of N from pure biochar-treated treatments (TB1.5 = 0.25%, TB2.0 = 0.23% and TB2.5 = 0.24%) was higher that the controlled treatment (0.16%). However, the amount of N in pure biochar-treated treatments was below that of the treatments with biochar incorporated with vermicompost (TMB1.5 = 0.36%, TMB2.0 = 0.42% and TMB2.5 = 0.49%). However, the addition of vermicompost alone or with RHB resulted in no significant difference (P < 0.05) in the wet weight of the Chinese kale roots compared to the control (Figure 1).

3.3. Chinese kale biomass

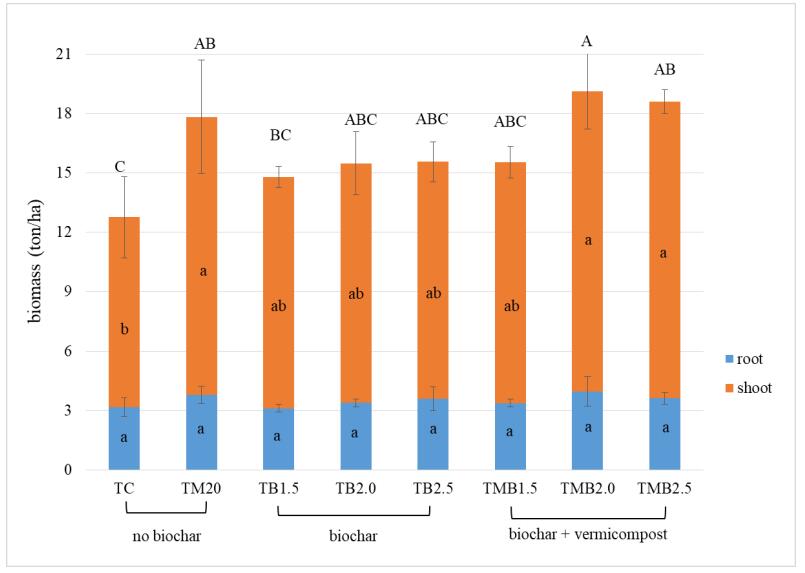

The highest total biomass of Chinese kale was obtained with the addition of 20 wt.% vermicompost plus 2.0 wt.% RHB (TMB2.0) as well as the highest biomass of roots and shoots at 0.1913 ton/ha and 0.8478 ton/ha, respectively, (Figure 2). However, this was not significantly higher than those obtained with vermicompost alone (TM20), while the addition of RHB at higher (TMB2.5) or lower (TMB1.5) levels resulted in a lower net biomass of Chinese kale than with vermicompost alone. Indeed, the root biomass was not significantly different between all eight treatments, and only treatments TM20 and TMB2.0 resulted in significantly higher yields (P < 0.05) than that for the TC. The addition of RHB alone without vermicompost numerically (but not significantly) increased the biomass above that of the control only at the lowest RHB level of 1.5 wt.%, and then decreased with increasing RHB levels. Thus, the addition of an appropriate amount of RHB (2.0 wt.%) with the vermicompost (20 wt.%) into the soil increased the biomass of Chinese kale (Figure 2).

3.4. Carbon concentration in Chinese kale

Carbon concentration in the Chinese kale was determined separately for the roots, shoots and leaves, as well the average of the whole plant. There were no significant differences in carbon levels in any of the three yield components or the total plant for all eight treatments. Numerically the carbon concentration was higher in the roots (37.69–41.14%) than in the shoots (36.40–37.32%) or leaves (35.78–37.89%), but these differences were not significant. Therefore, either adding only vermicompost or biochar into soil or adding the mixture of vermicompost and biochar into soil was not enough to induce difference in C concentration in root, shoot and leaves.

3.5. Carbon storage in the plant biomass

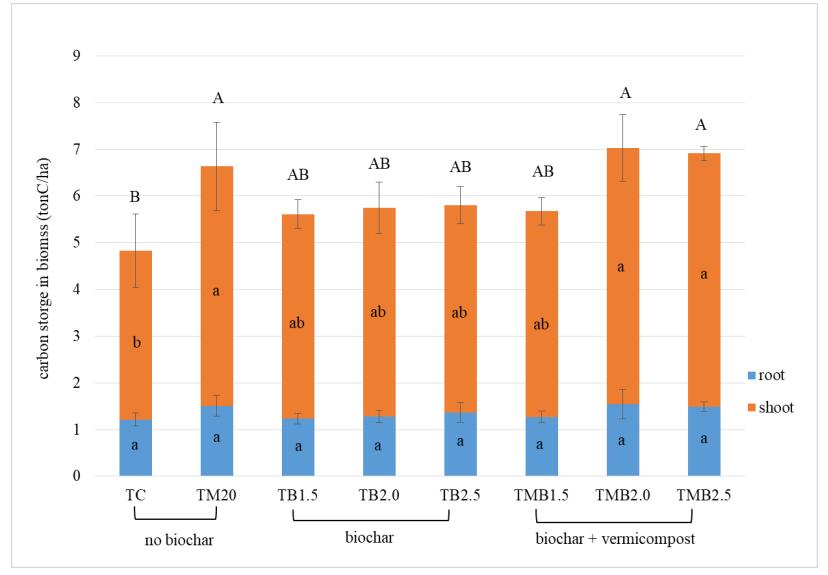

The highest level of carbon storage in the roots and shoots of Chinese kale was found in treatment TMB2.0 at 1.542 and 5.486 tonC/ha, respectively, as well as the highest total carbon storage (7.028 tonC/ha). The unsupplemented soil (TC) resulted in the lowest carbon storage in roots (1.212 tonC/ha), while treatment TB2.5 had the lowest carbon storage level in both the shoots (0.1669 tonC/ha) and the whole plant (0.2229 tonC/ha). Comparing the carbon storage in the Chinese kale biomass (Figure 3), treatment TMB2.0 had the numerically highest carbon storage in roots; however, this was not significantly different at P > 0.05 from all other treatments. However, TMB2.0 had the highest carbon storage in the shoots and total plant (P < 0.05) and was significantly higher than that for the control (TC) and soil supplemented with 2.0 wt.% or 2.5 wt.% RHB without vermicompost (TB2.0 and TB2.5).

3.6. Total carbon storage in the plant biomass and culture soil

The highest carbon storage in the plant biomass and soil was found in treatment TMB2.5 (53.4904 tonC/ha), followed by TMB2.0 (50.890 tonC/ha) and TM20 (44.646 tonC/ha), where the vermicompost plus RHB treatments (TMB2.0 and TMB2.5) resulted in a significantly higher carbon storage than in the control or soils with only RHB added (TB1.5, TB2.0 and TB2.5). Carbon storage in the soil exhibited a similar pattern (Table 2), where soil carbon storage increased with vermicompost alone (TM20) and with increasing amounts of added RHB (TMB2.5 > TMB2.0 > TMB1.5).

3.7. Physical characteristics of the soil and the amount of available nutrients after cultivation

Clay (%Clay 54) was used for cultivation in this study. The soil density was high, with poor drainage and porosity. Prior to cultivation, the soil bulk density was 0.903 g/cm3. However, after cultivation with Chinese kale, it was apparent that adding RHB together with vermicompost decreased bulk density (TMB1.5, TMB2.0 and TMB2.5). The mixture significantly reduced the bulk density in comparison to the control treatment (P < 0.05) but was not significantly different in comparison to the sole RHB treatment (P > 0.05) (Table 3). This was attributed to the ability of biochar to increase total soil pore volume and aeration [37,38,39,40].

As for soil chemical properties, the results indicated that the soil in every treatment became less alkaline (pH = 8.1) in comparison to samples taken prior to cultivation. The post-cultivation soil samples revealed that every sole biochar treatments (TB1.5, TB2.0 and TB2.5) became more alkaline that the control treatment (TC). However, treatment differences were non-significant at P > 0.05. Mixing vermicompost together with RHB increased soil pH. The amount of biochar added to the treatments influenced pH levels (TMB 1.5 > TMB2.0 > TMB2.5). EC in treatment with sole vermicompost (TM20) were the same as treatments with RHB and vermicompost (TMB1.5, TMB2.0 and TMB2.5) and showed a statistically significant difference from other treatments (TC, TB1.5, TB2.0 and TB2.5). The increase of EC in the soil was due to the fact that EC in vermicompost (2.63 dS/m) was much higher than EC in RHB (0.35 dS/m). However, analyzing CEC in every treatment, the results showed no statistically significant difference between each treatment, but the CEC in those treatments were still higher than the untreated control (CEC = 67.40 cmol/kg).

The amount of OM and primary nutrients (Total N, Available P and Exchangeable K) after cultivation were as follows. OM and primary nutrients in treatments with biochar and vermicompost (TMB1.5, TMB2.0 and TMB2.5) and treatment with sole vermicompost (TM20) were higher than in the treatments with sole biochar (TB1.5, TB2.0 and TB2.5) and untreated control (TC). OM was highest in TM20 (OM% = 7.18%), followed by TMB2.0 (OM = 6.75%) which yielded similar results to TMB1.5 and TMB2.5 (P > 0.05). The treatment with 20% RHB and vermicompost resulted in the highest amount of exchangeable K in the soil after cultivation. The results were statistically significantly higher compared with sole biochar treatments (TB1.5, TB2.0 and TM2.5), sole vermicompost (TM20) and the untreated control (TC). The amount of Total N and Available P were highest in the treatment with vermicompost and 2.0% RHB by weight. Soil samples from treatments with vermicompost and RHB and the treatment with sole vermicompost had significantly higher levels of Available P than the untreated control and treatments with sole RHB.

Post-cultivation analysis of the three primary soil nutrients revealed the highest levels in the TMB2.0 treatment (Total N = 0.38%, Avail. P = 190.00 mg/kg, Exch. K = 457.50 mg/kg). This treatment also produced the highest yields (19.14 ton/ha) and biomass (30.51 ton/ha). The results demonstrated that adding an appropriate amount of biochar could ameliorate the soil and contribute to higher crop yields. This was apparent in sole biochar treatments at 2.0 and 2.5 wt.% (TB2.0 and TB2.5), which yielded more consumable Chinese kale and total biomass than the untreated control. Moreover, total yields and total biomass of the TB2.0 and TB2.5 treatments were similar to the treatment with the least amount of vermicompost and biochar (TMB1.5).

4.

Discussion

4.1. Effect of RHB addition to soil on the yield of Chinese kale

Addition of RHB as a soil amendment significantly increased yield when added at an appropriate amount, consistent with previous studies [12,13,15]. Both the physical and chemical properties of biochar render it suitable as an effective soil amendment; its high surface area and pore size density confer important benefits to soil physical and chemical properties. This allows the RHB treatment to increase soil porosity, leading to a better drainage and soil aeration. The plant's roots are thus able to grow and penetrate the soil and nutrients are mover available under aerobic conditions. Moreover, the RHB, like other biochars, comprises aromatic hydrocarbons bonded with aromatic rings that are highly stable [1,2,3,8,14]. Moreover, its surface chemical structure includes hydroxyl and carboxyl groups (C-O, C = O, COOH and OH)

[1,37,38]. These functional groups facilitate ion exchange and nutrient adsorption over the surface of the biochar [3,12,39]. The combined high surface area of biochar and its high CEC leads to higher ion exchange between nutrients in the soil solution [40,41]. Moreover, a massive interstitial pore volume enables biochar to temporarily adsorb and store nutrients from the soil solution, releasing them over time for uptake by plant roots. This reduces nutrient leaching and environmental pollution, while allowing more continuous nutrient availability for plant growth [3,38,42,43], contributing to higher yields.

Biochar addition has been shown to significantly increase the effectiveness of nitrogen-based fertilizers [44], which is the main (often limiting) nutrient vital for plant growth. This was apparent in treatments with biochar that contained more N than in the untreated controls. The amount of N increased in treatments containing biochar and vermicompost, and the N amount was also higher than in the treatments incorporated with vermicompost alone. This is due to the ability of biochar to retain soil nutrients and reduce leaching into drainage water or beyond the root zone [1,2,8,9,44,56]. Soil amendment using biochar has also been shown to lead to significantly increased root biomass at each crop growth stage, as well as higher crop yields [15,45,46]. In this study, using RHB at an appropriate ratio together with vermicompost as an organic fertilizer, resulted in additional yield increases compared with using either alone. These results are consistent with previous studies examining different plants, such as kale [47], watermelon [9], soybean [13] and upland rice [12]. Although both biochar and organic fertilizers such as the RHB and vermicompost used in this study, enrich the soil with OM and primary nutrients, the OM in organic fertilizers is slowly degraded and mineralized by soil microorganisms, allowing the plant to absorb the digested OM to synthesize plant biomass [48,49,50]. Inorganic fertilizers result in a more immediate effect on crop growth compared with biochar or organic fertilizers. However, biochar acts as a medium for ion exchange between the plant nutrients in soil solution [49,51] and allows for active plant growth over a longer time. The porous and stability characters of biochar help store the plant's nutrients in the pores for a very long time [40,41,52] so the crop can absorb the nutrients all the time until they are fully grown. Moreover, biochar reduces nutrient loss by leaching from the root zone caused by rainfall or irrigation [8,12,51,53,54]. By also retaining water in its pores, biochar also helps ensure water availability throughout the season and alleviate local water scarcity that can seriously hamper crop growth. Therefore, agricultural soil augmented with both biochar and organic fertilizers can significantly increase plant growth, plant biomass and yields as well as improving soil health.

4.2. Using biochar to increase carbon storage in agriculture

In this study, the use of RHB as a soil supplement increased carbon storage both directly and indirectly, consistent with previous studies [6,39,55,56,57]. RHB's characteristics result from the conditions during the slow pyrolysis process, converting the rice husk into biochar. The pyrolysis process increased the amount of carbon from 38.3% in rice husk to 47.67% in RHB. The pyrolysis process also induced changes in carbon atoms, bonds and functional groups in the biomass. Carbon in RHB takes the form of aromatic C with high concentration. As a result, carbon in biochar is highly stable [58,59]. Its stability and low H/C ratio (less than 0.7) make it difficult to decompose [26,60,61], resulting in significantly higher levels of carbon storage in soils with added RHB.. Biosequestration results from carbon storage in the plant biomass itself [13,62]; this also increased in soils containing added RHB (2.5 wt.%) and 20 wt.% vermicompost. Even though RHB and vermicompost contain carbon, the amount of carbon in the vermicompost is less than in the RHB and is also in a form that is more easily decomposed compared with the carbon in RHB [14,51,63].

In this study, soil, rather than plant biomass, was responsible for the bulk of the carbon storage; thus RHB contributes more as a carbon sink than through biosequestration. Nevertheless, increasing crop biomass through RHB soil augmentation is beneficial to urban food security. Using biochar in agriculture could boost yields, increase carbon storage, reduce GHG emissions and contribute to food security [13,18,61,64,65], It can be easily applied to urban agriculture, e.g., on the rooftops of high-rise buildings. Moreover, incorporating biochar into agricultural soils contributes both directly and indirectly to carbon sequestration [5,6,8,18,32], with the amount of sequestered carbon dependent on the amount of incorporated biochar. Carbon sequestered in biomass increases in proportion to the quantity and biomass of the yield [5,6,11,13,14]. Moreover, incorporating biochar in agricultural soils also increased the yields of Chinese kale. Yields were highest in the treatments combining RHB with vermicompost; this was consistent with a previous study in rice conducted by Wijitkosum and Kallayasiri [12]. The study reported that biochar incorporation in rice fields resulted in increased yields, with the highest yields observed in treatments combining biochar and vermicompost. Therefore, incorporating biochar and vermicompost in urban agriculture can play a role in urban food security [16] and reduce pressure on surrounding rural areas to supply food to city dwellers. Long-distance transportation of food products generates greenhouse gas emissions (measure as food miles) [25,26]. Therefore, allocating space in high-rise buildings for vertical agriculture in urban areas where space is limited helps reduce food miles [27,28,29], an increase in carbon sequestration from using a highly stable biochar and a growth in food security in urban areas.

5.

Conclusion

Applying the appropriate ratio of RHB combined with vermicompost for planting vegetables in urban agriculture systems (e.g., on the roof of high-rise buildings) would increase food availability, contribute to carbon storage and enhance quality of life for residents. At a higher level, urban planners can designate dedicated areas for urban agriculture to facilitate effective urban management for food security and sustainable environmental management.

This study was limited by the fact that crops grown on the roofs of high-rise buildings in tropical countries were exposed directly to the scorching sunlight. The higher the building, the more exposed to the sun. In this study, shade was provided by a screenhouse built on top of the building using a metal frame and canvas. However, it is crucial that such structures are secured to prevent wind damage. Further studies are recommended to explore practical applications in urban agriculture. Moreover, collaboration between stakeholders, especially local authorities such as the Bangkok Metropolitan Administration, will be essential. Pilot projects could be undertaken on university buildings before extending to other urban locations elsewhere. This research has also attracted private sector actors interested in using biochar in high rise agricultural areas for carbon sequestration purposes.

Acknowledgments

This research was supported by the "Building a Smart Community for Climate Change and Natural Disasters Adaptation. Sub-project: Using biochar in urban farming areas for food security and carbon sequestration on high-rise buildings", 2016 Ratchadapisek Sompoch Endowment Fund for in-depth high potential research projects.

Conflict of interest

All authors declare no conflict of interest in this study.

DownLoad:

DownLoad: