Citation: Ankita Juneja, Ganti S. Murthy. Evaluating the potential of renewable diesel production from algae cultured on wastewater: techno-economic analysis and life cycle assessment[J]. AIMS Energy, 2017, 5(2): 239-257. doi: 10.3934/energy.2017.2.239

| [1] | Mulualem T. Yeshalem, Baseem Khan . Design of an off-grid hybrid PV/wind power system for remote mobile base station: A case study. AIMS Energy, 2017, 5(1): 96-112. doi: 10.3934/energy.2017.1.96 |

| [2] | Sonia Longo, Maurizio Cellura, Francesco Guarino, Vincenzo La Rocca, Giuseppe Maniscalco, Massimo Morale . Embodied energy and environmental impacts of a biomass boiler: a life cycle approach. AIMS Energy, 2015, 3(2): 214-226. doi: 10.3934/energy.2015.2.214 |

| [3] | Tilahun Nigussie, Wondwossen Bogale, Feyisa Bekele, Edessa Dribssa . Feasibility study for power generation using off- grid energy system from micro hydro-PV-diesel generator-battery for rural area of Ethiopia: The case of Melkey Hera village, Western Ethiopia. AIMS Energy, 2017, 5(4): 667-690. doi: 10.3934/energy.2017.4.667 |

| [4] | Daido Fujita . The prospects of clean hydrogen utilization in power generation industry. AIMS Energy, 2023, 11(5): 991-1011. doi: 10.3934/energy.2023047 |

| [5] | Badr Ouhammou, Fatima Zohra Gargab, Samir El idrissi kaitouni, Slimane Smouh, Rachid El mrabet, Mohammed Aggour, Abdelmajid Jamil, Tarik Kousksou . Energy saving potential diagnosis for Moroccan university campuses. AIMS Energy, 2023, 11(3): 576-611. doi: 10.3934/energy.2023030 |

| [6] | Yassine Charabi, Sabah Abdul-Wahab . The optimal sizing and performance assessment of a hybrid renewable energy system for a mini-gird in an exclave territory. AIMS Energy, 2020, 8(4): 669-685. doi: 10.3934/energy.2020.4.669 |

| [7] | Girma Misrak, Molina Marta, Assefa Abebayehu . Feasibility study of a wind powered water pumping system for rural Ethiopia. AIMS Energy, 2015, 3(4): 851-868. doi: 10.3934/energy.2015.4.851 |

| [8] | V. V. Thang, Thanhtung Ha . Optimal siting and sizing of renewable sources in distribution system planning based on life cycle cost and considering uncertainties. AIMS Energy, 2019, 7(2): 211-226. doi: 10.3934/energy.2019.2.211 |

| [9] | Mowffaq M. Oreijah, Mohammed Yunus . A parametric analysis to evaluate the performance metrics of power generation system involving Trilateral Flash Cycle using three different working fluids for low grade waste heat. AIMS Energy, 2019, 7(4): 483-492. doi: 10.3934/energy.2019.4.483 |

| [10] | Debela Tadele, Poritosh Roy, Fantahun Defersha, Manjusri Misra, Amar K. Mohanty . Life Cycle Assessment of renewable filler material (biochar) produced from perennial grass (Miscanthus). AIMS Energy, 2019, 7(4): 430-440. doi: 10.3934/energy.2019.4.430 |

Total energy consumption of United States in 2013 was 1.04 × 105 quadrillion joules, of which about 82% comes from fossil reserves and only 9.3% is contributed by renewable energy. Transportation sector is one of the biggest consumers of energy, which accounts for nearly one third of the total energy consumption worldwide and contributes to about 21% of greenhouse gas (GHG) emissions [1]. Concerns of depleting fossil fuels and increasing environmental burden has encouraged the exploration of additional renewable sources. Interest in algal biofuels can be attributed to the possibility of year round production at higher productivities compared to terrestrial crops, non-competition with food crops, reduced need for arable land and water treatment benefits with nutrient cycling. It has been studied that algae can produce 10-50 times more oil per unit area than conventional oil seed crops such as canola, jatropha and oil palm [2]. Another considerable advantage of algae is its ability to consume nutrients from wastewater and thus help in wastewater treatment, which solves another big challenge of clean water requirement. One of the challenges for microalgal derived biofuels is the dewatering of algae, as the alternative routes of lipid extraction with hexane, pyrolysis or gasification require the use of dry algae (85-95% solids) and drying is one of the most cost intensive process in the whole route of oil production, which can add up to 30% of the total cost [3]. Efforts are required to use the wet biomass directly for biofuel production to eliminate the energy required for dewatering/drying. Although wet lipid extraction methods including ultrasound-assisted extraction [4], simultaneous distillation and extraction process [5], microwave-assisted extraction [6] and supercritical fluid extraction [7] have been investigated by various researchers, the technologies require high cost and energy input. Hydrothermal liquefaction (HTL) is one of the technologies that fits this criteria of using wet algae. HTL is a thermal process of converting algae into high heating value bio-oil under high temperature and pressure.

Hydrothermal liquefaction (HTL) is gaining attraction as an alternative route for biofuels production from algal biomass. HTL reactions, involving dehydration, deoxygenation, and decarboxylation [8], occur at elevated temperatures (250-380 ℃), high pressure (5-30 MPa) and varying residence times (3-60 min) [9,10]. At such high temperatures and pressure, water still stays in liquid phase but the dielectric constant and the density of water is decreased relative to water at normal temperature and pressure, which causes water to become non-polar, highly reactive and miscible for organic components; thereby working as a catalyst. This results in hydrocarbon becoming more soluble in water [11]. HTL uses wet algae without the need for cell disruption, which eliminates the drying costs. Another advantage of HTL over traditional lipid extraction is the possibility of using low lipid algae as feedstock which is a significant benefit in case of fast growing algae with high carbohydrates and proteins but low lipid productivity, such as those commonly found in waste water treatment plants.

Biocrude obtained from HTL must be hydrotreated for reducing the overall oxygen content to produce usable form of fuel, renewable diesel. Renewable diesel yield from HTL (104, 000 m3/y) was observed to be 12% better than that of biodiesel from lipid extraction (91, 300 m3/y) [12]. Renewable diesel (1) can be directly used in diesel-powered vehicles without modifications, (2) is compatible with current diesel distribution infrastructure, (3) can be produced using existing oil refinery capacity, (4) can be used in advance emission control devices due to ultra-low sulfur content and (5) exhibits better performance than diesel [13].

Algal biofuels are currently proven on lab scale but commercialization of the process is still in its infancy. Long term viability of any feedstock or process not only depends on the yield of the final product, but also on sustained production capacity, maximized profits and minimized environmental burden. It is important to determine the overall energy efficiency along with capital and operating cost estimations to investigate the sustainability of a process. Techno economic analysis is an important tool to analyze the cost and energy viability of the process on large scale. Environmental impact, in terms of GHG emissions and fossil energy use, of the process can be calculated by performing the life cycle assessment. To obtain better insight into the current state of biofuel technology, this study evaluates the overall economics of renewable diesel production from algal biomass. The study will also help in identifying the key parameters/operations in the renewable diesel (RD) production process, which can be targeted for further improvements.

Life cycle analysis is a useful technique to assess impact of products, processes and services on the environment and can play an important role in comparing renewable diesel with other fuel alternatives based on environmental impact. Most of the previous studies performed on assessing environmental impacts of algal biofuels focus on biofuel production focused on production processes that involved fresh water/sea water with use of supplied nutrients [14,15]. This study, however, assess the production models that use wastewater as a source of water and nutrients to achieve a dual goal of biofuel production and wastewater treatment. Therefore, the overall objective of this study is to perform a comprehensive techno-economic analysis and limited life cycle assessment of RD production to analyze the economics and environmental impact of the production process and identify the key process that have the largest contribution in the overall RD production process.

Chlorella vulgaris (C. vulgaris) has shown a high potential for wastewater treatment during its growth [16]. Chlorella vulgaris is one of the promising algae strains for biofuels production, with high productivity (1.06 g/L/day), high rate of CO2 fixation (1.99 g/L/day), and tolerance to high concentrations to CO2 and compounds such as nitrogen oxides (NOx) and sulfur oxides (SOx) [17]. These characteristics make these algae suitable for growth in open ponds using wastewater as a nutrient source with added benefits of flue gas utilization to meet algae carbon requirements. Therefore C. vulgaris was used as algal feedstock to develop the model, as high growth, low lipid content algae such as C. vulgaris is suitable for hydrothermal liquefaction (HTL). Lipids, carbohydrates and protein content in C. vulgaris in this study is assumed to be 25%, 9% and 55% respectively on dry basis [18].

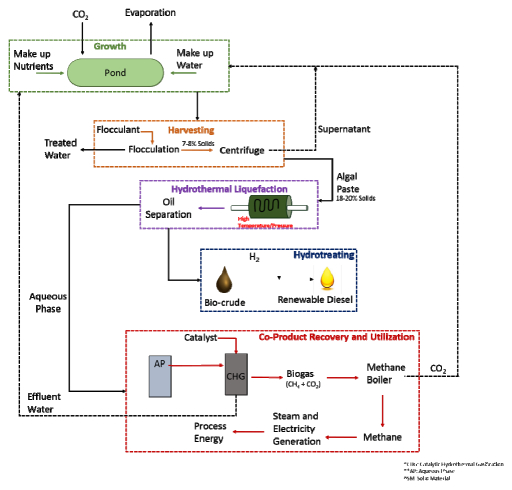

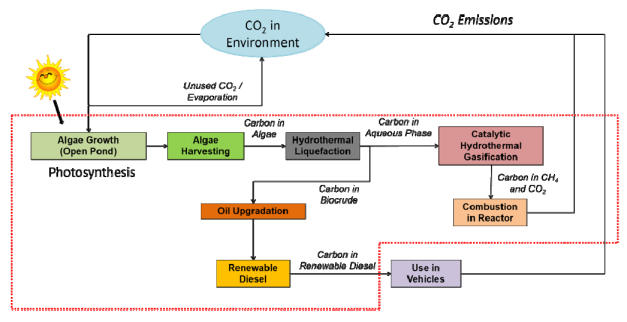

A process model was developed for treating incoming wastewater of 227 million L/day (60 million gallon/day) from local community using Super Pro Designer (Intelligen, Inc., Scotch Plains, NJ). The process model contains five sections: growth, harvesting, hydrothermal liquefaction, bio-oil hydrotreating and co-product recovery and utilization (catalytic hydrothermal gasification) (Figure 1).

Figure 1. Schematic illustration of modeled bio-oil plant.

Figure 1. Schematic illustration of modeled bio-oil plant.It was assumed that algae production facility receives adequate solar radiation to obtain productivity of 25 g/m2/day, and plant operates throughout the year for 330 days. The concentration of algae going out the pond was 0.38 g/L (4 days retention time). Productivity of 25 g/m2/day and a need for treatment of 227 million L/day wastewater, requires construction of 85 ponds of 4 ha each with a total area of 340 ha. The total algae flow from the ponds to the harvesting section was 3550 kg/h. Accounting for a 2% loss of algae during flocculation and 0.01% during centrifugation, a total of 3478 kg/hr algae was processed for hydrothermal liquefaction, which produced 1222 kg/hr biocrude oil. Hydrotreating of biocrude produced 990 kg/hr (340 gal/hr) RD. The remnants of HTL (16, 455 kg/hr, which includes~4% organic matter and~95% water) were used to produce methane rich biogas (60% methane and 40% CO2) by catalytic hydrothermal liquefaction, producing 710 kg/hr biogas. The CHP (combined heat and power generation) unit with efficiency of 38% electricity production [19] using direct biogas produced 2412 kW electricity, most of which was used to fulfil the plant requirements and the rest was exported out of the plant.

The plant is assumed to operate for 330 days/year. Price basis for all the economic calculations was taken as 2015. Costs of specific equipment (open ponds, clarifier, centrifuge, hydrothermal liquefaction reactor, hydrothermal gasification reactor and hydrotreating reactor) for renewable diesel production process were calculated based on previously reported cost models [20,21,22] (listed in supplementary Table 1). Costs were adjusted to year 2015 using the equation 1:

| Costin2015=Costinbaseyear∗(2015indexbaseyearindex) | (1) |

Cost of other equipment was based on the built-in cost models in SuperPro designer. The scale up of the equipment was done using the conversion from equation 2:

| Scaledcost=originalscalecost∗(ScaleupcapacityOriginalcapacity)n | (2) |

where n is the scaling factor (typically 0.6-0.7).

Algae plant was assumed to be based on a modular design based on raceway ponds (L:W:D = 890 m :44 m :0.3 m). The growth rate of algae was calculated based on Monod kinetic parameters of algal growth with nitrate as limiting substrate calculated by laboratory experiments (equation 3).

| μ=μmaxSS+ks | (3) |

where μ is the specific growth rate of microalgae, μmax is the maximum specific growth rate, S in this study is the concentration of nitrate in wastewater and ks is the half saturation constant.

Mixing of algae slurry in the open pond using paddle wheels is necessary to avoid sedimentation, distribute nutrients, and maintain a uniform temperature and pH to enhance algae productivity [23]. The power requirement for the paddle wheel is calculated using equation 4 [20].

| P=QWΔd102e | (4) |

where P is the power requirement (kW), Q is the flow of the culture (m3/s) (calculated by velocity × cross-sectional area), W is the specific weight of the culture (kg m-3), Δd is the head loss of water, e is the efficiency of paddle wheel (40% assumed [22]) and 102 is the conversion factor. The velocity of water flowing with paddle wheel is assumed to be 15 cm/s [20] and the cross-sectional area can be calculated as depth × width/2 (6 m2). Additional head loss of water in the pond (Δd) occurs along the length of the pond and as water flows around two 180° bend with baffles. Both the head losses can be calculated using the Manning's equation. Total head loss can be calculated as the summation of the two losses (equation 5) [22].

| Δd=v2n2(LR43)+Kv22g | (5) |

where v is the mean velocity (m/s), n is the roughness factor (0.18 for clay lining), R is the channel hydraulic radius (m), L is the channel length (m), K is the kinetic loss coefficient for 180° bends (theoretically 2).

With surface area (cross-sectional area) of 6 m2 and wetted perimeter as 20.6 m, the hydraulic radius is calculated as 0.29 m. Total head loss was calculated as 0.0238 m (0.0046 m around two 180° bends and 0.0192 m along the total channel length of 1790 m).

The pond is assumed to be built with compacted earth and lined with clay locally available avoiding the high cost of plastic liner [22]. A report suggested an increase in pond construction from $136, 000 for clay lined to $277, 000 with plastic lining (year 2010 reference) for a 4-ha raceway pond [22]. The total cost of one open pond was $154, 600, and the breakdown of the cost is presented in Table 1. Flue gas (rich in CO2) from a power plant (Table 2) at a distance of up to 4.5 km (three miles) is transported by pipes for addition to the growth pond. It is assumed that utilization efficiency of CO2 in flue gas directly injected into algae ponds is more than 90% [24]. Some water is recycled back from centrifugation step (along with some nutrients), and rest of makeup water is provided by wastewater stream assumed to be transported from treatment plant 2 miles away. The composition of wastewater is presented in Table 2 [25]. Algae can utilize nutrients available in wastewater for growth which also helps in treatment of wastewater. Wastewater stream, thus, reduces the use of makeup nutrients required for algal growth. Any deficient nutrient was replenished with pure nutrient (considering only nitrates and phosphates in this study).

| Cost (per hectare) (Cost updated to 2015) |

Cost of 1 open pond (4 ha) (Cost updated to 2015) |

|

| Cost of open pond site | $3640/ha | $14560 |

| Cost of open pond construction (wall and structure) | $14450/ha | $57800 |

| Paddle wheel | $7285/ha | $29140 |

| CO2 delivery (pipes and pumps) | $9180/ha | $36720 |

| Internal distribution of CO2 (sumps) | $4090/ha | $16360 |

| Total open pond cost | $38645/ha | $154600 |

| Composition of flue gas [52] | Composition of wastewater [25] | ||

| Component | Mass composition | Component | Mass composition |

| Nitrogen | 76.5% | Water | 99.7% |

| Carbon dioxide | 12.8% | Other Solids | 0.12% |

| Water | 6.2% | Nitrates | 800 ppm |

| Oxygen | 4.4% | Inorganic carbon | 400 ppm |

| NOx | 420 ppm | Salts | 100 ppm |

| SOx | 420 ppm | Sulfates | 50 ppm |

| Carbon monoxide | 50 ppm | Phosphates | 15 ppm |

It is assumed that algae grows to a steady-state concentration and is continuously harvested at the rate equal to the growth rate. Algae is harvested in two steps: bulk dewatering and thickening. Dewatering can be achieved using flocculation or floatation. Although floatation is an effective process as algae floats up faster than settling down in flocculation [3], power consumption in pumping air for dispersed air flotation if high, making the process expensive. Also, the choice of coagulant/collector is very critical in air flotation [26]. Therefore, flocculation process was chosen for bulk dewatering step using cationic starch as flocculent [27]. A high sedimentation of 95% algae is reported to be achieved with 30 minutes residence time with a concentration of 10 mg flocculent per liter of culture [27]. This step yields a concentration of 15 g/L. Each clarifier used (settling pond) has a working volume of 12, 500 m3. A total of 3.75 ha of land was used for three settling units required for the operation. The thickening of algae is obtained by centrifugation process, providing the final concentration of 200 g/L (20% solids) algae. The throughput of centrifuge was 90 m3/h with the cost of one unit as $277, 000. In the current study, use of centrifuge was assumed as final step in algae harvesting process, however other studies have used sun drying, belt press, bed drying as other options to increase algal concentration [12].

The solids concentration reported in literature for HTL of algae is 10-20% [28,29]. For the purpose of this study, it was assumed that the 20% solids concentrated algae obtained from previous centrifugation step, transported using positive displacement pump, which are offered by vendors to pump slurries with 20% solids [30], is directly used in HTL reactor. The optimal HTL process conditions for maximum oil productivity (~37% reported) [28] reported in literature [10,28] were chosen for the process modeling 340 ℃, 200 bar pressure and residence time of three minutes. Choice of residence time was based on studies that have indicated possibility of higher yields with shorter residence times (1-10 minutes) [31,32]. The bio-crude yield was calculated based on the additive relation proposed by Biller and Ross [18], with protein yield as 10% [11], carbohydrate yield as 32% and lipid yield as 95% [33]. For algae flow rate of 3478 kh/hr, the biocrude yield was calculated as 35% (1221.9 kg/hr). The pressurized slurry is preheated at 335 ℃ before entering into the reactor. The reactor was chosen to be plug flow reactor because of lower economics at this scale (capital and operating cost) than continuously stirred tank reactor, used in other studies [8]. The HTL conditions and elemental analysis of bio-oil are reported in Table 3.

| Temperature (℃) | 340 ℃ |

| Pressure | 200 bar |

| Solids concentration in feed (wt.%) | 20% |

| Residence time | 3 min |

| HTL oil yield (wt.%) | 37% |

| Aqueous co-product (wt.%) | 36% |

| HTL bio-oil analysis wt.% C H O N S |

77.3% 9.4% 6.1% 6.2% 0.65% |

| Bio-oil moisture content | 2.8% |

| Bio-oil HHV | 24 MJ/kg |

The coproduct stream from algal oil extraction via hexane extraction or HTL is rich in organic matter, which makes it suitable to be converted to biogas [8,15]. The most common route of conversion is anaerobic digestion, but in case of HTL, aqueous byproducts are rich in nitrogen (about 70% of feedstock nitrogen ends up in aqueous phase). The ideal range of C:N for successful anaerobic digestion is 20:1-30:1. Jena et al. [34] measured 3.92% carbon and 1.84% nitrogen in the aqueous phase after HTL of Spirulina platensis, indicating a C:N ratio of 2.1:1. High nitrogen content in the aqueous phase makes it unsuitable to be digested in anaerobic digester. Such sludge is suitable for treatment in catalytic hydrothermal gasification (CHG), a process that converts the nitrogen and carbon of the wet organic matter to biogas with use of a catalyst. The CHG treatment is very efficient for the conversion of organic carbon in the aqueous phase (99.2%) [35]. Gasification dominates in temperatures above 647 K [35]. CHG leads to formation of a methane rich (60%) biogas [36] and the conversion of organics is independent of the operating pressure after the temperatures are above 647 K [37].

The biocrude obtained after hydrothermal liquefaction has to be upgraded to remove/reduce oxygen, nitrogen and sulfur before use in transportation vehicles. Hydrotraeting is done by treating the bio-oil with hydrogen (3.75% of wet bio-oil) at 350-400 ℃ at 3.4-10.3 MPa (300 ℃ and 3.5 MPa used in this study) in presence of a catalyst (CoMo/alumina-F in this study). This treatment converts the oxygen in the biocrude to CO2 and H2O, nitrogen to ammonia and sulfur to H2S resulting in renewable diesel product with a density of 770 g/L [21] and a heating value of 44 MJ/kg. The cost of hydrogen production in petroleum refinery is $1.21/kg [38] and the requirement of hydrogen is 0.0375 kg/kg wet bio-oil [21].

The goal of the study is to investigate the GHG emissions and energy use during the life cycle of renewable diesel production from algae. The study analyzed the impact of RD production process from algae via hydrothermal liquefaction. The functional unit for the model was taken as 1000 MJ of RD energy (22.73 kg or 29.5L RD). Most of the data for the LCA model was taken from the techno-economic model described in earlier sections.

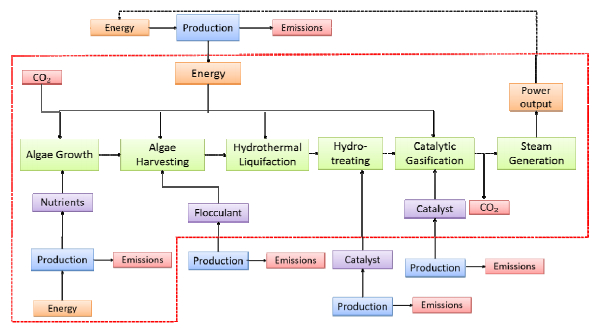

The model was divided into four sections: algal production and harvesting, bio-oil production and co-product recovery and bio-oil distribution. Selection of system boundary is the most critical decision which affects the computations of energy consumption and emissions. The system boundary selected for this study is shown in Figure 2.

Figure 2. System boundary for life cycle analysis of RD production from algae (Red dotted line shows the system boundary considered in the study).

Figure 2. System boundary for life cycle analysis of RD production from algae (Red dotted line shows the system boundary considered in the study).The co-product allocation method is another major selection that can significantly influence the results of life cycle analysis [39]. Electricity was the only co-product from the plant. System expansion (displacement) approach [39] was used to calculate the co-product credits, which assumes that the electricity produced from biogas replaces the electricity requirement for the plant operations and offsets the energy use and GHG emissions to produce the electricity that would otherwise be produced using fossil fuels. The emissions were calculated in terms of gram CO2 equivalent using global warming potential factors of 1, 25 and 298 for CO2, CH4 and N2O, respectively.

Net energy value (NEV) and net energy ratio (NER) are the two terms defined on LCA to assess the energy efficiencies and fossil fuel displacement values [40]. NEV and NER were calculated using equations 6 and 7. The NER of a system is defined as the ratio of total energy produced over the energy required for all plant operations. For a product to be sustainable (energy in the fuel > fossil energy used), NER should be greater than 1.

| NEV=Energyoffunctionalunit−−energyuseproducefunctionalunit | (6) |

| NER=∑Energyproduced∑Energyrequirements | (7) |

The model was developed in GREET (Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation). The values for nutrients, catalyst, hydrogen and flocculant used and energy requirement were derived from the techno-economic model.

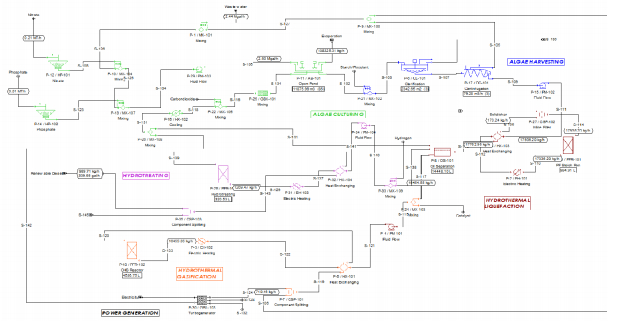

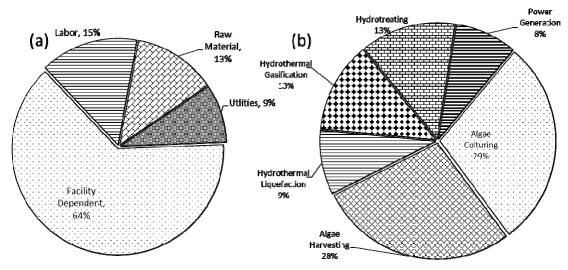

Model of bio-oil production from algae (60 million gallon wastewater per day) was simulated in SuperPro Designer (Figure 3) for a plant life of 20 years. Techno-economic model for the production of renewable diesel in the nth plant design resulted in the cost of production of RD as $1.75/L ($6.62/gal). The capital cost for bio-oil production plant were estimated to be $105 MM with renewable diesel (RD) production of 10 million liters/year (2.7 million gallon/year). Overall economics of the process are presented in Table 4. Installed equipment cost (equipment and installation cost) accounted for nearly 38% of the total direct fixed capital costs. The rest would include piping, building and other indirect costs (engineering, construction, contractor's fee). Breakdown of operating cost as facility dependent costs, raw material costs and other costs (labor and utilities) for the RD production processes is illustrated in Figure 4a. The major portion was facility dependent cost (64%), which includes the costs associated with equipment maintenance, depreciation of the fixed capital cost, and miscellaneous costs such as insurance, local (property) taxes and possibly other overhead-type of factory expenses. The raw material cost accounted for 13% of the total operating cost, with flocculant (starch) and catalyst for hydrothermal gasification being the major fraction (31% and 23% respectively). Most of the major nutrients required for growth were supplied by the wastewater (78% nitrates and 98% phosphates). Similarly, about 21% CO2 was supplemented with the flue gas.

Figure 3. SuperPro model of bio-oil plant from algae.

Figure 3. SuperPro model of bio-oil plant from algae.| Total Investment (MM $) | 104.96 |

| Operating Cost (MM $/yr) | 17.88 |

| RD (MMgal/yr) | 2.69 |

| RD unit cost ($/l ($/gal)) | 1.75(6.62) |

| Direct fixed capital cost (MM $)* | 99.39 |

| Equipment cost (MM $) | 26.86 |

| Installation cost (MM $) | 10.43 |

| *Direct fixed capital cost includes equipment and installation cost along with indirect costs. | |

Figure 4. (a) Contribution of facility dependent, labor dependent, raw material and utilities cost during production of RD from algae and (b) distribution of RD price among different sections.

Figure 4. (a) Contribution of facility dependent, labor dependent, raw material and utilities cost during production of RD from algae and (b) distribution of RD price among different sections.The results of techno-economic analysis to be used for life cycle analysis are summarized in Table 5 and 6. Energy use for a section is calculated was the ratio of the energy used in that particular section to the total energy produced (energy of RD). The values of energy use for different sections of RD production system are in agreement with previously performed life cycle analysis [41].

| Amount (kg/year) | Amount (kg/kg RD) | Amount (kg/functional unit) | |

| Algae (P) | 28111000 | 3.524 | 80.98 |

| Nitrate (C) | 1632000 | 0.208 | 4.70 |

| Phosphate (C) | 55000 | 0.007 | 0.16 |

| CO2(C) | 40411000 | 5.155 | 116.41 |

| Starch (C) | 707000 | 0.090 | 2.04 |

| Catalyst (C) | 4000 | 0.001 | 0.01 |

| Hydrogen (C) | 377000 | 0.048 | 1.09 |

| Biocrude (P) | 9677000 | 1.235 | 27.88 |

| RD (P) | 7838000 | 1.000 | 22.58 |

| *(C) onsumption and (P) roduction. | |||

| Section | Electricity used (kWh/yr) | Electricity used (MJ/kg RD) | Energy Use (MJ/MJ RD) |

| Algae Growth | 6508340 | 2.63 | 0.060 |

| Harvesting | 3641694 | 1.47 | 0.033 |

| HTL | 2611733 | 1.05 | 0.024 |

| Gasification | 6011259 | 2.42 | 0.055 |

| Upgradation | 2555741 | 1.03 | 0.023 |

| Co-production | 21778226 | 8.79 | 0.200 |

| Exported | 449459 | 0.18 | 0.004 |

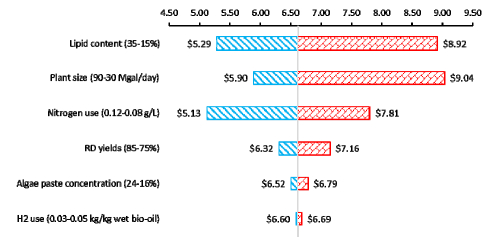

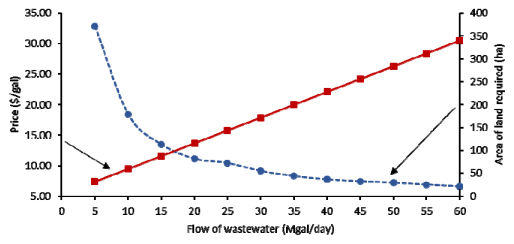

Sensitivity analysis was performed on various inputs/operations for change in final price of renewable diesel (Figure 5). The tornado chart shows that all the parameters had significant impact on the final price of bio-oil. Lipid content of algae was the major factor affecting the price of renewable diesel, as lipids are converted to biocrude with up to 100% efficiency [33,42]. Lipid content of the strain was changed with corresponding change in protein content (nitrogen starvation leads to increase in lipids with a reduction in proteins [43]). These results are in agreement with an earlier study for production of biodiesel from microalgae that also found lipid content to be the most sensitive parameter in price of biodiesel [15]. Second major factor was the size of plant, which was shown to have considerable effect on price of RD (Figure 6). Although the first major factor is strain dependent, the second is operational parameter, which can be altered for improved economics. The changes in the amount of hydrogen for upgrading the biocrude to renewable diesel did not have a large impact on the final price because of the low quantity of hydrogen used per unit biocrude oil.

Figure 5. Effect of parameters on price of renewable diesel.

Figure 5. Effect of parameters on price of renewable diesel. Figure 6. Effect of wastewater amount on price of RD and area required for plant.

Figure 6. Effect of wastewater amount on price of RD and area required for plant.The price of RD was calculated as $6.62/gal, which includes for $0.86/gallon hydrotreating cost. The price of biofuel from algae has been reported to fall in the variable range of from $0.92/ gal to $42.6/gal [44]. The distribution of RD price among different sections is shown in Figure 4b. Algae culturing and harvesting contributed the largest fraction of the total cost of RD (~56%), in agreement with ranges reported in literature [21]. Raw material contributed to 13% of the total price of which starch added as flocculant was the highest contributor (~33%), followed by catalyst use (~24%), and hydrogen (~24%) and nutrients (~19%).

The comparison of the price of biocrude and renewable diesel are compared with other studies in Figure 7. All the prices were adjusted to 2015 for comparison purpose with inflation rate of 2%. In the wide range of biofuel from algae price, the price of RD in this study is on the lower limits. One of the main reasons for the low cost of production was the use of clay lining over more expensive plastic lining. The cost of RD was found to be $2.1/l ($7.93/gal) with the use of plastic lining ad increasing the cost of pond accordingly. Another reason was low makeup nutrients required for growth as wastewater adequately covered most of the nitrate and phosphate requirement. The location of plant was another favorable aspect, such that a high volume of wastewater was available for algal growth. The impact of plant size on final product price has already been demonstrated in Figure 6.

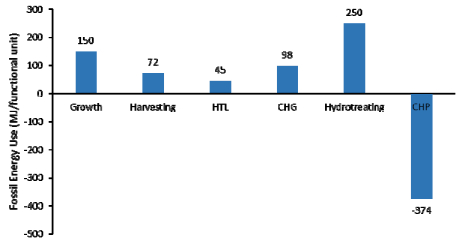

A well to pump life cycle model for production of RD was developed in GREET. The fossil energy use for production of RD was 241.6 MJ per 1000 MJ of energy produced, which was about 80% lower than that from GREET life cycle model of conventional diesel from crude oil [48]. The fossil energy use was calculated by deducting the co-product (electricity production) from the total energy. The distribution of fossil energy use among different sections of RD production is shown in Figure 8. It can be observed that upgrading the biocrude oil had major contribution to the fossil energy use, due to hydrogen use for hydrotreating. The fossil energy use for CHP is negative implying excess electricity generation.

Figure 8. Distribution of fossil energy use over different sections of RD production.

Figure 8. Distribution of fossil energy use over different sections of RD production.Net energy value for RD production was 758.4 MJ per 1000 MJ energy, which is higher than the conventional diesel (-207 MJ) [48] and lower than the crude oil from algae using lipid extraction (914 MJ) [49]. NER for four fuels compared is shown in Figure 9. The value of NER was less than one for gasoline indicating that the fossil energy input is higher than the energy in the fuel. The NER for algal oil is the highest, mainly because the crude oil is yet to be upgraded for use in transportation vehicles, which has a high fossil energy requirement in the form of hydrogen.

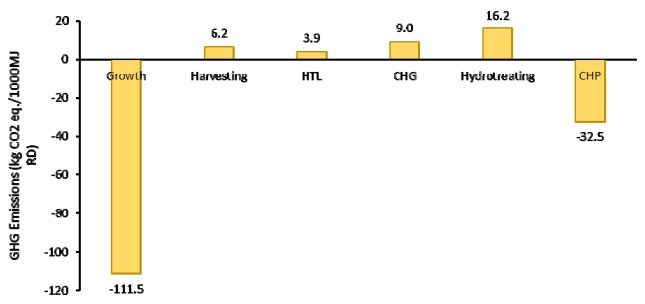

The total GHG emissions during life cycle of RD production from algae were estimated to be 110 kg CO2 equivalent per 1000 MJ of renewable diesel (-3.73 kg CO2 eq./L RD). The GHG emissions for RD were found to be lower than the well to pump analysis of algal oil (-24 kg CO2 equivalent per 1000 MJ) [49] and conventional diesel (21 kg CO2 equivalent per 1000 MJ) [48]. The negative value for the GHG emission during production of RD is mainly because of system boundary selection. In well to pump analysis, the CO2 emissions during use of fuel are not considered, which results in negative GHG emissions. Another reason for negative GHG emissions is the co-product energy available during RD production process, which displaces the GHG emissions produced by fossil fuels required to produce electricity in the plant. Similar negative values (-46.5 kg CO2e per 1000 MJ of RD) were reported for well to pump analysis of renewable diesel production from algae earlier [41]. However, well to wheel analysis of the same study estimated GHG emission of 31 kg CO2e per 1000 MJ of RD.

Figure 10 shows the GHG emissions in different stages of RD production. The GHG emissions during growth of algae are negative because of CO2 sequestration in the photosynthesis process. Maximum GHG emissions were observed in hydrotreating process. The carbon flow (balance) throughout the life cycle of RD is shown in Figure 11. Red dotted line in the Figure indicates the system boundary, where sequestration of CO2 from the atmosphere was included whereas use in the vehicle is excluded (explained in earlier sections).

Figure 10. GHG emissions produced per functional unit during various stages of life cycle of RD production.

Figure 10. GHG emissions produced per functional unit during various stages of life cycle of RD production. Figure 11. Carbon balance during life cycle analysis of RD production (Red dotted line indicates system boundary chosen for this study).

Figure 11. Carbon balance during life cycle analysis of RD production (Red dotted line indicates system boundary chosen for this study).A comprehensive techno-economic analysis and life cycle assessment was performed to evaluate the economic feasibility and environmental impact of the production of renewable diesel from algae via the hydrothermal liquefaction process. Cost of production of RD was calculated to be $6.62/gal, which was on the lower side of the broad range reported in literature. Highest contributors to the cost of RD were algae culturing and harvesting. The cost difference between crude bio-oil and hydrotreated renewable diesel was found to be $0.84. Lipid content of the algae and plant size were the 2 critical factors in deciding the cost of RD. The total greenhouse gas emissions in the process of RD production were -110 kg CO2 equivalent per 1000 MJ of renewable diesel and the total fossil energy used in the process was 241.6 MJ per 1000 MJ of energy produced. The negative GHG emissions were attributed to the system boundary of the life cycle analysis. Techno-economic and life cycle assessments indicated that production of RD from algae is competitive to other alternatives to diesel production.

All authors declare no conflicts of interest in this paper.

| [1] |

Ndong R, Montrejaud VM, Saint GO, et al. (2009) Life cycle assessment of biofuels from Jatropha curcas in West Africa: a field study. GCB Bioenerg 1: 197–210. doi: 10.1111/j.1757-1707.2009.01014.x

|

| [2] |

Chisti Y (2007) Biodiesel from microalgae. Biotechnol adv 25: 294–306. doi: 10.1016/j.biotechadv.2007.02.001

|

| [3] | Becker EW (1994) Microalgae: biotechnology and microbiology, Cambridge University Press, 10: 165. |

| [4] |

Adam F, Abert VM, Peltier G, et al. (2012) "Solvent-free" ultrasound-assisted extraction of lipids from fresh microalgae cells: a green, clean and scalable process. Bioresource Technol 114: 457–465. doi: 10.1016/j.biortech.2012.02.096

|

| [5] |

Tanzi CD, Vian MA, Chemat F (2013) New procedure for extraction of algal lipids from wet biomass: a green clean and scalable process. Bioresource Technol 134: 271–275. doi: 10.1016/j.biortech.2013.01.168

|

| [6] |

Cheng J, Yu T, Li T, et al. (2013) Using wet microalgae for direct biodiesel production via microwave irradiation. Bioresource Technol 131: 531–535. doi: 10.1016/j.biortech.2013.01.045

|

| [7] |

Halim R, Gladman B, Danquah MK, et al. (2011) Oil extraction from microalgae for biodiesel production. Bioresource Technol 102: 178–185. doi: 10.1016/j.biortech.2010.06.136

|

| [8] |

Zhu Y, Biddy MJ, Jones SB, et al. (2014) Techno-economic analysis of liquid fuel production from woody biomass via hydrothermal liquefaction (HTL) and upgrading. Appl Energ 129: 384–394. doi: 10.1016/j.apenergy.2014.03.053

|

| [9] |

Akhtar J, Amin NAS (2011) A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew Sust Energ Rev 15: 1615–1624. doi: 10.1016/j.rser.2010.11.054

|

| [10] | Brown TM, Duan P, Savage PE (2010) Hydrothermal liquefaction and gasification of Nannochloropsis sp. Energ Fuel 24: 3639–3646. |

| [11] |

Peterson AA, Vogel F, Lachance RP, et al. (2008) Thermochemical biofuel production in hydrothermal media: a review of sub-and supercritical water technologies. Energ Environ Sci 1: 32–65. doi: 10.1039/b810100k

|

| [12] | Delrue F, Li-Beisson Y, Setier PA, et al. (2013) Comparison of various microalgae liquid biofuel production pathways based on energetic, economic and environmental criteria. Bioresource Technol 136: 205–212. |

| [13] | Thomas E, David WR, Timothy RG (2010) California renewable diesel multimedia evaluation, The University of California, Davis, Berkeley. |

| [14] | Amer L, Adhikari B, Pellegrino J (2011) Technoeconomic analysis of five microalgae-to-biofuels processes of varying complexity. Bioresource Technol 2011: 9350–9359. |

| [15] |

Davis R, Aden A, Pienkos PT (2011) Techno-economic analysis of autotrophic microalgae for fuel production. Appl Energ 88: 3524–3531. doi: 10.1016/j.apenergy.2011.04.018

|

| [16] | Ahmad F, Khan AU, Yasar A (2013) The potential of Chlorella vulgaris for wastewater treatment and biodiesel production. Pakistan J Bot 45: 461–465. |

| [17] | Tebbani S, Filali R, Lopes F, et al. (2014) CO2 biofixation by Microalgae: automation process, John Wiley & Sons. |

| [18] |

Biller P, Ross A (2011) Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresource Technol 102: 215–225. doi: 10.1016/j.biortech.2010.06.028

|

| [19] | Wett B, Buchauer K, Fimml C (2007) In energy self-sufficiency as a feasible concept for wastewater treatment systems, IWA Leading Edge Technology Conference, Singapore, Asian Water, 21–24. |

| [20] | Borowitzka M (2005) Culturing microalgae in outdoor ponds, In: algal culturing techniques, Andersen, Ed. Academic Press, NY, USA, 205–217. |

| [21] | Jones S, Davis R, Zhu Y, et al. (2014) Process design and economics for the conversion of algal biomass to hydrocarbons: whole algae hydrothermal liquefaction and upgrading, Department of Energy Bioenergy Technologies Office, US. |

| [22] | Lundquist TJ, Woertz IC, Quinn N, et al. (2011) A realistic technology and engineering assessment of algae biofuel production. Energ Biosci I, 1–153. |

| [23] | Jonker J, Faaij A (2013) Techno-economic assessment of micro-algae as feedstock for renewable bio-energy production. Appl Energ 102: 461–475. |

| [24] | Sheehan J, Dunahay T, Benemann J, et al. (1998) A look back at the US department of energy's aquatic species program: biodiesel from algae, National Renewable Energy Laboratory Golden, CO, 328. |

| [25] | Ellis TG (2004) Chemistry of wastewater, Encyclopedia of Life Support System (EOLSS). |

| [26] |

Chen Y, Liu J, Ju YH (1998) Flotation removal of algae from water. Colloid Surface B 12: 49–55. doi: 10.1016/S0927-7765(98)00059-9

|

| [27] |

Hansel PA (2014) Efficient flocculation of microalgae for biomass production using cationic starch. Algal Res 5: 133–139. doi: 10.1016/j.algal.2014.07.002

|

| [28] |

Jazrawi C, Biller P, Ross AB (2013) Pilot plant testing of continuous hydrothermal liquefaction of microalgae. Algal Res 2: 268–277. doi: 10.1016/j.algal.2013.04.006

|

| [29] |

Jena U, Das K, Kastner J (2011) Effect of operating conditions of thermochemical liquefaction on biocrude production from Spirulina platensis. Bioresource Technol 102: 6221–6229. doi: 10.1016/j.biortech.2011.02.057

|

| [30] | Berglin EJ, Enderlin CW, Schmidt AJ (2012) Review and assessment of commercial vendors/options for feeding and pumping biomass slurries for hydrothermal liquefaction, Pacific Northwest National Laboratory, Office of Scientific & Technical Information Technical Reports. |

| [31] |

Garcia AL, Vos MP, Torri C, et al. (2013) Recycling nutrients in algae biorefinery. Chem Sus Chem 6: 1330–1333. doi: 10.1002/cssc.201200988

|

| [32] | Faeth JL, Valdez PJ, Savage PE (2013) Fast hydrothermal liquefaction of Nannochloropsis sp. to produce biocrude. Energ Fuel 27: 1391–1398. |

| [33] | Holliday RL, King JW, List GR (1997) Hydrolysis of vegetable oils in sub-and supercritical water. Ind Eng Chem Res 36: 932–935. |

| [34] |

Jena U, Vaidyanathan N, Chinnasamy S (2011) Evaluation of microalgae cultivation using recovered aqueous co-product from thermochemical liquefaction of algal biomass. Bioresource Technol 102: 3380–3387. doi: 10.1016/j.biortech.2010.09.111

|

| [35] | Elliott DC, Biller P, Ross AB (2014) Hydrothermal liquefaction of biomass: developments from batch to continuous process. Bioresource Technol 178: 147–156. |

| [36] | Elliott DC, Neuenschwander GG, Hart TR (2009) Catalytic hydrothermal gasification of lignin-rich biorefinery residues and algae, Pacific Northwest National Laboratory Pnnl. |

| [37] |

Elliott DC (2008) Catalytic hydrothermal gasification of biomass. Biofuel Bioprod Bioref 2: 254–265. doi: 10.1002/bbb.74

|

| [38] | Cruz FE, Oliveira JS (2008) Petroleum refinery hydrogen production unit: exergy and production cost evaluation. Int J Thermodyn 11: 187–193. |

| [39] |

Kim S, Dale BE (2002) Allocation procedure in ethanol production system from corn grain I system expansion. Int J Life Cy Assess 7: 237–243. doi: 10.1007/BF02978879

|

| [40] |

Juneja A, Kumar D, Murthy GS (2013) Economic feasibility and environmental life cycle assessment of ethanol production from lignocellulosic feedstock in Pacific Northwest US. J Renew Sust Energ 5: 023142. doi: 10.1063/1.4803747

|

| [41] |

Frank ED, Elgowainy A, Han J, et al. (2013) Life cycle comparison of hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. Mitig Adapt Strat Gl 18: 137–158. doi: 10.1007/s11027-012-9395-1

|

| [42] | King J, Holliday R, List G (1999) Hydrolysis of soybean oil. in a subcritical water flow reactor. Green Chem 1: 261–264. |

| [43] | Juneja A, Ceballos RM, Murthy GS (2013) Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: a review. Energies 6: 4607–4638. |

| [44] |

Sun A, Davis R, Starbuck M, et al. (2011) Comparative cost analysis of algal oil production for biofuels. Energy 36: 5169–5179. doi: 10.1016/j.energy.2011.06.020

|

| [45] | Benemann JR, Oswald WJ (1996) Systems and economic analysis of microalgae ponds for conversion of CO2 to biomass, Final report, California Univ., Berkeley, CA, Dept. of Civil Engineering. |

| [46] | Xiang X (2013) Techno-economic analysis of algal lipid fuels, Dissertation, Oregon State University. |

| [47] |

Richardson JW, Johnson MD, Outlaw JL (2012) Economic comparison of open pond raceways to photo bio-reactors for profitable production of algae for transportation fuels in the Southwest. Algal Res 1: 93–100. doi: 10.1016/j.algal.2012.04.001

|

| [48] | Palou RI, Wang MQ (2010) Updated estimation of energy efficiencies of US petroleum refineries, Argonne National Laboratory, US. |

| [49] | Frank E, Han J, Palou RI, et al. (2011) Life-cycle analysis of algal lipid fuels with the greet model, Center for Transportation Research, Energy Systems Division, Argonne National Laboratory, Oak Ridge. |

| [50] | Jorquera O, Kiperstok A, Sales EA (2010) Comparative energy life-cycle analyses of microalgal biomass production in open ponds and photobioreactors. Bioresource Technol 101: 1406–1413. |

| [51] | Weissman JC, Goebel R (1987) Design and analysis of microalgal open pond systems for the purpose of producing fuels: a subcontract report, Solar Energy Research Inst., Golden, CO., USA. |

| [52] | Xu X, Song C, Wincek R, et al. (2003) Separation of CO2 from power plant flue gas using a novel CO2 "molecular basket" adsorbent. Fuel Chem Div Prepr 48: 162–163. |

| 1. | Ankita Juneja, Ganti S. Murthy, Model predictive control coupled with economic and environmental constraints for optimum algal production, 2018, 250, 09608524, 556, 10.1016/j.biortech.2017.11.047 | |

| 2. | Xiangyu Gu, Liang Yu, Na Pang, Jose Salomon Martinez-Fernandez, Xiao Fu, Shulin Chen, Comparative techno-economic analysis of algal biofuel production via hydrothermal liquefaction: One stage versus two stages, 2020, 259, 03062619, 114115, 10.1016/j.apenergy.2019.114115 | |

| 3. | L. Soto-Sierra, S. Kulkarni, S. L. Woodard, Z. L. Nikolov, Processing of permeabilized Chlorella vulgaris biomass into lutein and protein-rich products, 2020, 32, 0921-8971, 1697, 10.1007/s10811-020-02055-x | |

| 4. | Tamás Mizik, Gábor Gyarmati, Economic and Sustainability of Biodiesel Production—A Systematic Literature Review, 2021, 3, 2571-8797, 19, 10.3390/cleantechnol3010002 | |

| 5. | Bunushree Behera, Nazimdhine Aly, P. Balasubramanian, Biophysical model and techno-economic assessment of carbon sequestration by microalgal ponds in Indian coal based power plants, 2019, 221, 09596526, 587, 10.1016/j.jclepro.2019.02.263 | |

| 6. | Gulab Singh, S. K. Patidar, Development and Applications of Attached Growth System for Microalgae Biomass Production, 2020, 1939-1234, 10.1007/s12155-020-10195-8 | |

| 7. | Verónica Campos-Guzmán, M. Socorro García-Cáscales, Nieves Espinosa, Antonio Urbina, Life Cycle Analysis with Multi-Criteria Decision Making: A review of approaches for the sustainability evaluation of renewable energy technologies, 2019, 104, 13640321, 343, 10.1016/j.rser.2019.01.031 | |

| 8. | Amir Akbari, Paul I. Barton, Integrating Genome-Scale and Superstructure Optimization Models in Techno-Economic Studies of Biorefineries, 2019, 7, 2227-9717, 286, 10.3390/pr7050286 | |

| 9. | Richard Gordon, Richard Gordon, Clifford R Merz, Shawn Gurke, Benoît Schoefs, 2019, 9781119370215, 583, 10.1002/9781119370741.ch22 | |

| 10. | Enrique Medina Martos, Ioan-Robert Istrate, Javier Dufour, 2020, 9780128162040, 435, 10.1016/B978-0-12-816204-0.00019-9 | |

| 11. | Mayank Kumar, Adetoyese Olajire Oyedun, Amit Kumar, A Comparative Technoeconomic Analysis of Algal Thermochemical Conversion Technologies for Diluent Production, 2020, 8, 2194-4288, 1900828, 10.1002/ente.201900828 | |

| 12. | Arun K. Vuppaladadiyam, Pepijn Prinsen, Abdul Raheem, Rafael Luque, Ming Zhao, Sustainability Analysis of Microalgae Production Systems: A Review on Resource with Unexploited High-Value Reserves, 2018, 52, 0013-936X, 14031, 10.1021/acs.est.8b02876 | |

| 13. | Devinder Singh, Giovanna Gonzales-Calienes, 2021, Chapter 11, 978-981-15-7517-4, 243, 10.1007/978-981-15-7518-1_11 | |

| 14. | Na Wu, Cesar M. Moreira, Yingxiu Zhang, Nguyet Doan, Shunchang Yang, Edward J. Phlips, Spyros A. Svoronos, Pratap C. Pullammanappallil, 2019, Chapter 6, 978-1-83881-849-4, 10.5772/intechopen.86090 | |

| 15. | Didem Özçimen, Benan İnan, Anıl Tevfik Koçer, Meyrem Vehapi, 2018, Chapter 10, 978-1-78923-332-2, 10.5772/intechopen.73702 | |

| 16. | Panneerselvam Ranganathan, Sivaraman Savithri, Techno-economic analysis of microalgae-based liquid fuels production from wastewater via hydrothermal liquefaction and hydroprocessing, 2019, 284, 09608524, 256, 10.1016/j.biortech.2019.03.087 | |

| 17. | Mayank Kumar, Adetoyese Olajire Oyedun, Amit Kumar, 2019, 9780128168561, 715, 10.1016/B978-0-12-816856-1.00029-4 | |

| 18. | Jamison Watson, Tengfei Wang, Buchun Si, Wan-Ting Chen, Aersi Aierzhati, Yuanhui Zhang, Valorization of hydrothermal liquefaction aqueous phase: pathways towards commercial viability, 2020, 77, 03601285, 100819, 10.1016/j.pecs.2019.100819 | |

| 19. | Shiv Prasad, Dheeraj Rathore, Anoop Singh, 2021, Chapter 11, 978-981-15-9695-7, 249, 10.1007/978-981-15-9696-4_11 | |

| 20. | Esveidi Montserrat Valdovinos-García, Juan Barajas-Fernández, María de los Ángeles Olán-Acosta, Moisés Abraham Petriz-Prieto, Adriana Guzmán-López, Micael Gerardo Bravo-Sánchez, Techno-Economic Study of CO2 Capture of a Thermoelectric Plant Using Microalgae (Chlorella vulgaris) for Production of Feedstock for Bioenergy, 2020, 13, 1996-1073, 413, 10.3390/en13020413 | |

| 21. | Stan Pankratz, Mayank Kumar, Adetoyese Olajire Oyedun, Eskinder Gemechu, Amit Kumar, Environmental performances of diluents and hydrogen production pathways from microalgae in cold climates: Open raceway ponds and photobioreactors coupled with thermochemical conversion, 2020, 47, 22119264, 101815, 10.1016/j.algal.2020.101815 | |

| 22. | Mohit Aggarwal, Neelancherry Remya, The State-of-the-Art Production of Biofuel from Microalgae with Simultaneous Wastewater Treatment: Influence of Process Variables on Biofuel Yield and Production Cost, 2021, 1939-1234, 10.1007/s12155-021-10277-1 | |

| 23. | Liqun Jiang, Yizhen Li, Haiyan Pei, Algal–bacterial consortia for bioproduct generation and wastewater treatment, 2021, 149, 13640321, 111395, 10.1016/j.rser.2021.111395 | |

| 24. | Gábor Gyarmati, Tamás Mizik, A biodízel-termelés gazdasági és fenntarthatósági vizsgálata szakirodalom-elemzéssel, 2022, 69, 00234346, 643, 10.18414/KSZ.2022.5.643 | |

| 25. | Jessica Muniz Melo, Marina Ronchesel Ribeiro, Tiago Santos Telles, Higo Forlan Amaral, Diva Souza Andrade, Microalgae cultivation in wastewater from agricultural industries to benefit next generation of bioremediation: a bibliometric analysis, 2022, 29, 0944-1344, 22708, 10.1007/s11356-021-17427-0 | |

| 26. | Janakan S. Saral, R.S. Ajmal, Panneerselvam Ranganathan, 2022, 9780128233061, 355, 10.1016/B978-0-12-823306-1.00011-X | |

| 27. | Ishita Chanana, Parneet Kaur, Lokender Kumar, Pradeep Kumar, Sourabh Kulshreshtha, Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market, 2023, 9, 2311-5637, 202, 10.3390/fermentation9030202 | |

| 28. | Sirong He, Bahram Barati, Xun Hu, Shuang Wang, Carbon migration of microalgae from cultivation towards biofuel production by hydrothermal technology: A review, 2023, 240, 03783820, 107563, 10.1016/j.fuproc.2022.107563 | |

| 29. | Esveidi Montserrat Valdovinos-García, Moisés Abraham Petriz-Prieto, María de los Ángeles Olán-Acosta, Juan Barajas-Fernández, Adriana Guzmán-López, Micael Gerardo Bravo-Sánchez, Production of Microalgal Biomass in Photobioreactors as Feedstock for Bioenergy and Other Uses: A Techno-Economic Study of Harvesting Stage, 2021, 11, 2076-3417, 4386, 10.3390/app11104386 | |

| 30. | Botian Hao, Donghai Xu, Ya Wei, Yunfei Diao, Le Yang, Liangliang Fan, Yang Guo, Mathematical models application in optimization of hydrothermal liquefaction of biomass, 2023, 243, 03783820, 107673, 10.1016/j.fuproc.2023.107673 | |

| 31. | Serpil Madden, Kaylee Alles, Yaşar Demirel, Measuring sustainability of renewable diesel production using a multi‐criteria decision matrix , 2021, 15, 1932-104X, 1621, 10.1002/bbb.2272 | |

| 32. | Changlei Xia, Abhijeet Pathy, Balasubramanian Paramasivan, Prabakaran Ganeshan, Kondusamy Dhamodharan, Ankita Juneja, Deepak Kumar, Kathirvel Brindhadevi, Sang-Hyoun Kim, Karthik Rajendran, Comparative study of pyrolysis and hydrothermal liquefaction of microalgal species: Analysis of product yields with reaction temperature, 2022, 311, 00162361, 121932, 10.1016/j.fuel.2021.121932 | |

| 33. | Prangya Ranjan Rout, Mukesh Goel, Daya Shankar Pandey, Caitlin Briggs, Venkatesa Prabhu Sundramurthy, Nirmalya Halder, Anee Mohanty, Sanjay Mukherjee, Sunita Varjani, Technological advancements in valorisation of industrial effluents employing hydrothermal liquefaction of biomass: Strategic innovations, barriers and perspectives, 2023, 316, 02697491, 120667, 10.1016/j.envpol.2022.120667 | |

| 34. | K.D. González-Gloria, Rosa M. Rodríguez-Jasso, E. Aparicio, Mónica L. Chávez González, Emily T. Kostas, Héctor A. Ruiz, Macroalgal biomass in terms of third-generation biorefinery concept: Current status and techno-economic analysis – A review, 2021, 16, 2589014X, 100863, 10.1016/j.biteb.2021.100863 | |

| 35. | Shir Reen Chia, Kit Wayne Chew, Hui Yi Leong, Shih-Hsin Ho, Heli Siti Halimatul Munawaroh, Pau Loke Show, CO2 mitigation and phycoremediation of industrial flue gas and wastewater via microalgae-bacteria consortium: Possibilities and challenges, 2021, 425, 13858947, 131436, 10.1016/j.cej.2021.131436 | |

| 36. | Anıl Tevfik Koçer, Benan İnan, Sedef Kaptan Usul, Didem Özçimen, Mustafa Tahsin Yılmaz, İbrahim Işıldak, Exopolysaccharides from microalgae: production, characterization, optimization and techno-economic assessment, 2021, 52, 1517-8382, 1779, 10.1007/s42770-021-00575-3 | |

| 37. | Eleni Koutra, Dimitris P. Zagklis, Konstantina Tsigkou, Sameh Samir Ali, Michael Kornaros, 2023, 9780323918695, 53, 10.1016/B978-0-323-91869-5.00011-9 | |

| 38. | Xin Li, Jian Liu, Jiansong Tian, Zhicheng Pan, Yangwu Chen, Fei Ming, Rui Wang, Lin Wang, Houzhen Zhou, Junjie Li, Zhouliang Tan, Co-cultivation of microalgae-activated sludge for municipal wastewater treatment: Exploring the performance, microbial co-occurrence patterns, microbiota dynamics and function during the startup stage, 2023, 374, 09608524, 128733, 10.1016/j.biortech.2023.128733 | |

| 39. | Arathi Sreenikethanam, Subhisha Raj, J. Rajesh Banu, Poornachandar Gugulothu, Sunita Varjani, Amit K. Bajhaiya, Algal lipids for biofuel production: strategies, environmental impacts, downstream processing and commercialization, 2022, 1568-7767, 10.1007/s11101-022-09824-1 | |

| 40. | Mohammad Alherbawi, Prakash Parthasarathy, Tareq Al-Ansari, Hamish R. Mackey, Gordon McKay, Potential of drop-in biofuel production from camel manure by hydrothermal liquefaction and biocrude upgrading: A Qatar case study, 2021, 232, 03605442, 121027, 10.1016/j.energy.2021.121027 | |

| 41. | Shyamali Sarma, Shaishav Sharma, Darshan Rudakiya, Jinal Upadhyay, Vinod Rathod, Aesha Patel, Madhuri Narra, Valorization of microalgae biomass into bioproducts promoting circular bioeconomy: a holistic approach of bioremediation and biorefinery, 2021, 11, 2190-572X, 10.1007/s13205-021-02911-8 | |

| 42. | Bunushree Behera, S Mari Selvam, Paramasivan Balasubramanian, Hydrothermal processing of microalgal biomass: Circular bio-economy perspectives for addressing food-water-energy nexus, 2022, 359, 09608524, 127443, 10.1016/j.biortech.2022.127443 | |

| 43. | Janakan S. Saral, Ajmal Rasheeda Satheesh, Panneerselvam Ranganathan, Economic and environmental analysis of algal biorefinery for the production of renewable fuels and co-product, 2022, 14, 25901745, 100189, 10.1016/j.ecmx.2022.100189 | |

| 44. | Zhuangzhuang Liu, Zhiwei Yan, Fen Liu, Jun Fang, Speciation and transformation of nitrogen for swine manure thermochemical liquefaction, 2022, 12, 2045-2322, 10.1038/s41598-022-16101-w | |

| 45. | Yoong Kit Leong, Jo-Shu Chang, Waste stream valorization-based low-carbon bioeconomy utilizing algae as a biorefinery platform, 2023, 178, 13640321, 113245, 10.1016/j.rser.2023.113245 | |

| 46. | Rubens Costa Nogueira, Francisco Simão Neto, Paulo Gonçalves de Sousa Junior, Roberta Bussons Rodrigues Valério, Juliana de França Serpa, Ana Michele da Silva Lima, Maria Cristiane Martins de Souza, Rita Karolinny Chaves de Lima, Ada Amélia Sanders Lopes, Artemis Pessoa Guimarães, Rafael Leandro Fernandes Melo, Maria Alexsandra de Sousa Rios, José Cleiton Sousa dos Santos, Research trends and perspectives on hydrothermal gasification in producing biofuels, 2023, 27724271, 100199, 10.1016/j.nexus.2023.100199 | |

| 47. | Srujana Kathi, Siril Singh, Rajni Yadav, Anand Narain Singh, Alaa El Din Mahmoud, Wastewater and sludge valorisation: a novel approach for treatment and resource recovery to achieve circular economy concept, 2023, 5, 2673-2718, 10.3389/fceng.2023.1129783 | |

| 48. | Chaoyang Wei, Yilin Xu, Long Xu, Jian Liu, Hao Chen, Comparative life-cycle assessment of various harvesting strategies for biogas production from microalgae: Energy conversion characteristics and greenhouse gas emissions, 2023, 289, 01968904, 117188, 10.1016/j.enconman.2023.117188 | |

| 49. | Ali Omidkar, Hao Xu, Zhaofei Li, Kamran Haddadian, Hua Song, Techno-economic and life cycle assessment of renewable diesel production via methane-assisted catalytic waste cooking oil upgrading, 2023, 09596526, 137512, 10.1016/j.jclepro.2023.137512 | |

| 50. | Zainul Abideen, Raziuddin Ansari, Maria Hasnain, Timothy J. Flowers, Hans-Werner Koyro, Ali El-Keblawy, Mohamed Abouleish, Muhammed Ajmal Khan, Potential use of saline resources for biofuel production using halophytes and marine algae: prospects and pitfalls, 2023, 14, 1664-462X, 10.3389/fpls.2023.1026063 | |

| 51. | Ziba Borazjani, Farzad Bayat Mastalinezhad, Reza Azin, Shahriar Osfouri, Global Perspective of Hydrothermal Liquefaction of Algae: a Review of the Process, Kinetics, and Economics Analysis, 2023, 1939-1234, 10.1007/s12155-023-10615-5 | |

| 52. | Fahimeh Esmi, Shima Masoumi, Venu Babu Borugadda, Ajay K. Dalai, 2024, 9780128203613, 71, 10.1016/B978-0-12-820361-3.00012-7 | |

| 53. | Venkatesh Balan, James Pierson, Hasan Husain, Sandeep Kumar, Christopher Saffron, Vinod Kumar, Potential of using microalgae to sequester carbon dioxide and processing to bioproducts, 2023, 25, 1463-9262, 7934, 10.1039/D3GC02286B | |

| 54. | Shir Reen Chia, Jing Ling, Wen Yi Chia, Saifuddin Nomanbhay, Tonni Agustiono Kurniawan, Kit Wayne Chew, Future bioenergy source by microalgae–bacteria consortia: a circular economy approach, 2023, 1463-9262, 10.1039/D3GC02228E | |

| 55. | Jie Yu, Xiaoyu Lin, Jingchen Huang, Wangfang Ye, Qian Lan, Shaorong Du, Zilin Liu, Yijing Wu, Zeyuan Zhao, Xin Xu, Guifang Yang, Rahil Changotra, Yulin Hu, Yulong Wu, Chenyu Yan, Jie Yang, Quan (Sophia) He, Recent advances in the production processes of hydrothermal liquefaction biocrude and aid-in investigation techniques, 2023, 218, 09601481, 119348, 10.1016/j.renene.2023.119348 | |

| 56. | Meiqi Wang, Jing Xu, Jialin Zou, Hongzhi Ling, Jingping Ge, Yimeng Lin, Wenxiang Ping, Isolation and identification of Chlorella sorokiniana HDMA-16 and its cultivation potential in flax retting wastewater, 2023, 22119264, 103361, 10.1016/j.algal.2023.103361 | |

| 57. | Kaylee Alles, Yaşar Demirel, Measuring risk of renewable diesel production processes using a multi-criteria decision strategy, 2024, 00456535, 141695, 10.1016/j.chemosphere.2024.141695 | |

| 58. | Kuber Singh Mehra, Varun Goel, Rajat Kumar, An integrated multi-attribute decision framework for sustainability assessment of renewable diesel fuel production pathways, 2024, 309, 01968904, 118461, 10.1016/j.enconman.2024.118461 | |

| 59. | Ali Omidkar, Kamran Haddadian, Hua Song, 2024, 9780443190766, 403, 10.1016/B978-0-443-19076-6.00011-X | |

| 60. | Muntasir Shahabuddin, Nikolaos Kazantzis, Andrew R Teixeira, Michael T. Timko, One techno-economic analysis to rule them all: Instant prediction of hydrothermal liquefaction economic performance with a machine learned analytic equation, 2024, 24, 25901745, 100756, 10.1016/j.ecmx.2024.100756 | |

| 61. | Janakan S. Saral, Dekketi G.C. Vikram Reddy, Panneerselvam Ranganathan, 2025, 9780443292545, 381, 10.1016/B978-0-443-29254-5.00016-3 | |

| 62. | Ishaq Kariim, Ramadhani Bakari, Muhammad Wasi Syed, Ji-Yeon Park, In-Gu Lee, Thomas Kivevele, 2025, 1501, 9780841296008, 105, 10.1021/bk-2025-1501.ch006 | |

| 63. | Tianjiao Cheng, Andante Hadi Pandyaswargo, Hiroshi Onoda, 2025, Chapter 22, 978-981-97-9075-3, 373, 10.1007/978-981-97-9076-0_22 | |

| 64. | Kuppan Praveen, Sudharsanam Abinandan, Kadiyala Venkateswarlu, Mallavarapu Megharaj, Acid-tolerant microalgae-based winery wastewater treatment: performance evaluation and techno-economic analysis, 2025, 383, 03014797, 125335, 10.1016/j.jenvman.2025.125335 | |

| 65. | Rasangika Thathsaranee Weligama Thuppahige, Leonie Barner, Mahboobeh Shahbazi, Gabriel Fraga, Lalehvash Moghaddam, A comprehensive review of sustainable valorisation of lignocellulosic biomass and plastic waste into biofuels and chemicals via co-liquefaction, 2025, 202, 0956053X, 114827, 10.1016/j.wasman.2025.114827 | |

| 66. | Hongbo Du, Raghava R. Kommalapati, Exploring Lignocellulose-Based Renewable Diesel’s Potential for Texas Freight, 2025, 12, 2076-3298, 157, 10.3390/environments12050157 |

| Cost (per hectare) (Cost updated to 2015) |

Cost of 1 open pond (4 ha) (Cost updated to 2015) |

|

| Cost of open pond site | $3640/ha | $14560 |

| Cost of open pond construction (wall and structure) | $14450/ha | $57800 |

| Paddle wheel | $7285/ha | $29140 |

| CO2 delivery (pipes and pumps) | $9180/ha | $36720 |

| Internal distribution of CO2 (sumps) | $4090/ha | $16360 |

| Total open pond cost | $38645/ha | $154600 |

| Composition of flue gas [52] | Composition of wastewater [25] | ||

| Component | Mass composition | Component | Mass composition |

| Nitrogen | 76.5% | Water | 99.7% |

| Carbon dioxide | 12.8% | Other Solids | 0.12% |

| Water | 6.2% | Nitrates | 800 ppm |

| Oxygen | 4.4% | Inorganic carbon | 400 ppm |

| NOx | 420 ppm | Salts | 100 ppm |

| SOx | 420 ppm | Sulfates | 50 ppm |

| Carbon monoxide | 50 ppm | Phosphates | 15 ppm |

| Temperature (℃) | 340 ℃ |

| Pressure | 200 bar |

| Solids concentration in feed (wt.%) | 20% |

| Residence time | 3 min |

| HTL oil yield (wt.%) | 37% |

| Aqueous co-product (wt.%) | 36% |

| HTL bio-oil analysis wt.% C H O N S |

77.3% 9.4% 6.1% 6.2% 0.65% |

| Bio-oil moisture content | 2.8% |

| Bio-oil HHV | 24 MJ/kg |

| Total Investment (MM $) | 104.96 |

| Operating Cost (MM $/yr) | 17.88 |

| RD (MMgal/yr) | 2.69 |

| RD unit cost ($/l ($/gal)) | 1.75(6.62) |

| Direct fixed capital cost (MM $)* | 99.39 |

| Equipment cost (MM $) | 26.86 |

| Installation cost (MM $) | 10.43 |

| *Direct fixed capital cost includes equipment and installation cost along with indirect costs. | |

| Amount (kg/year) | Amount (kg/kg RD) | Amount (kg/functional unit) | |

| Algae (P) | 28111000 | 3.524 | 80.98 |

| Nitrate (C) | 1632000 | 0.208 | 4.70 |

| Phosphate (C) | 55000 | 0.007 | 0.16 |

| CO2(C) | 40411000 | 5.155 | 116.41 |

| Starch (C) | 707000 | 0.090 | 2.04 |

| Catalyst (C) | 4000 | 0.001 | 0.01 |

| Hydrogen (C) | 377000 | 0.048 | 1.09 |

| Biocrude (P) | 9677000 | 1.235 | 27.88 |

| RD (P) | 7838000 | 1.000 | 22.58 |

| *(C) onsumption and (P) roduction. | |||

| Section | Electricity used (kWh/yr) | Electricity used (MJ/kg RD) | Energy Use (MJ/MJ RD) |

| Algae Growth | 6508340 | 2.63 | 0.060 |

| Harvesting | 3641694 | 1.47 | 0.033 |

| HTL | 2611733 | 1.05 | 0.024 |

| Gasification | 6011259 | 2.42 | 0.055 |

| Upgradation | 2555741 | 1.03 | 0.023 |

| Co-production | 21778226 | 8.79 | 0.200 |

| Exported | 449459 | 0.18 | 0.004 |

| Cost (per hectare) (Cost updated to 2015) |

Cost of 1 open pond (4 ha) (Cost updated to 2015) |

|

| Cost of open pond site | $3640/ha | $14560 |

| Cost of open pond construction (wall and structure) | $14450/ha | $57800 |

| Paddle wheel | $7285/ha | $29140 |

| CO2 delivery (pipes and pumps) | $9180/ha | $36720 |

| Internal distribution of CO2 (sumps) | $4090/ha | $16360 |

| Total open pond cost | $38645/ha | $154600 |

| Composition of flue gas [52] | Composition of wastewater [25] | ||

| Component | Mass composition | Component | Mass composition |

| Nitrogen | 76.5% | Water | 99.7% |

| Carbon dioxide | 12.8% | Other Solids | 0.12% |

| Water | 6.2% | Nitrates | 800 ppm |

| Oxygen | 4.4% | Inorganic carbon | 400 ppm |

| NOx | 420 ppm | Salts | 100 ppm |

| SOx | 420 ppm | Sulfates | 50 ppm |

| Carbon monoxide | 50 ppm | Phosphates | 15 ppm |

| Temperature (℃) | 340 ℃ |

| Pressure | 200 bar |

| Solids concentration in feed (wt.%) | 20% |

| Residence time | 3 min |

| HTL oil yield (wt.%) | 37% |

| Aqueous co-product (wt.%) | 36% |

| HTL bio-oil analysis wt.% C H O N S |

77.3% 9.4% 6.1% 6.2% 0.65% |

| Bio-oil moisture content | 2.8% |

| Bio-oil HHV | 24 MJ/kg |

| Total Investment (MM $) | 104.96 |

| Operating Cost (MM $/yr) | 17.88 |

| RD (MMgal/yr) | 2.69 |

| RD unit cost ($/l ($/gal)) | 1.75(6.62) |

| Direct fixed capital cost (MM $)* | 99.39 |

| Equipment cost (MM $) | 26.86 |

| Installation cost (MM $) | 10.43 |

| *Direct fixed capital cost includes equipment and installation cost along with indirect costs. | |

| Amount (kg/year) | Amount (kg/kg RD) | Amount (kg/functional unit) | |

| Algae (P) | 28111000 | 3.524 | 80.98 |

| Nitrate (C) | 1632000 | 0.208 | 4.70 |

| Phosphate (C) | 55000 | 0.007 | 0.16 |

| CO2(C) | 40411000 | 5.155 | 116.41 |

| Starch (C) | 707000 | 0.090 | 2.04 |

| Catalyst (C) | 4000 | 0.001 | 0.01 |

| Hydrogen (C) | 377000 | 0.048 | 1.09 |

| Biocrude (P) | 9677000 | 1.235 | 27.88 |

| RD (P) | 7838000 | 1.000 | 22.58 |

| *(C) onsumption and (P) roduction. | |||

| Section | Electricity used (kWh/yr) | Electricity used (MJ/kg RD) | Energy Use (MJ/MJ RD) |

| Algae Growth | 6508340 | 2.63 | 0.060 |

| Harvesting | 3641694 | 1.47 | 0.033 |

| HTL | 2611733 | 1.05 | 0.024 |

| Gasification | 6011259 | 2.42 | 0.055 |

| Upgradation | 2555741 | 1.03 | 0.023 |

| Co-production | 21778226 | 8.79 | 0.200 |

| Exported | 449459 | 0.18 | 0.004 |